On March 28, the 6th China Manufacturing Power Forum was held in Baoding, Hebei Province. At the forum, new development concepts such as “innovation-driven”, “intelligent manufacturing”, and “green development” have been mentioned many times, revealing the new direction of my country’s industrial development in the future, and emphasizing the strategic thinking of the transformation of the kinetic energy of my country’s manufacturing industry from new to old. Achieve high-quality development in reform and innovation.

As an enterprise with high-end equipment business as its main business, Nantong Runbang Heavy Machinery Co., Ltd. (a wholly-owned subsidiary of Shenzhen Runbang Co., Ltd., a listed company on the Shenzhen Stock Exchange, hereinafter referred to as: Runbang Heavy Machinery) insists on technological innovation as the forerunner and continues to promote products Innovation and process innovation drive the high-quality development of the company, thoroughly implement the spirit of the "Two Sessions", and under the guidance of the 14th Five-Year Plan of the country and the 2035 long-term goal, a series of actions have been implemented for the intelligent and green development of the company’s high-end equipment products. Sexual and precise measures.

Drive product intelligence, innovation and development, new power

GENMA, an independent brand of Runbang Heavy Machinery, focuses on providing the market with high-quality lifting equipment and port machinery and other equipment. The GENMA brand insists on breakthroughs and innovations in the technical field, making products smarter and better serving customers.

GENMA mobile port cranes (MHC) are used in various comprehensive terminals such as containers, bulk cargo, and multi-purpose. They can load and unload a variety of cargo such as containers, LNG tanks, general cargo and bulk materials, and are suitable for everything from barges to super Panama ships. Of various ship types.

This series of products are equipped with a number of intelligent technologies to realize the safe operation of the equipment and maximize the benefits.

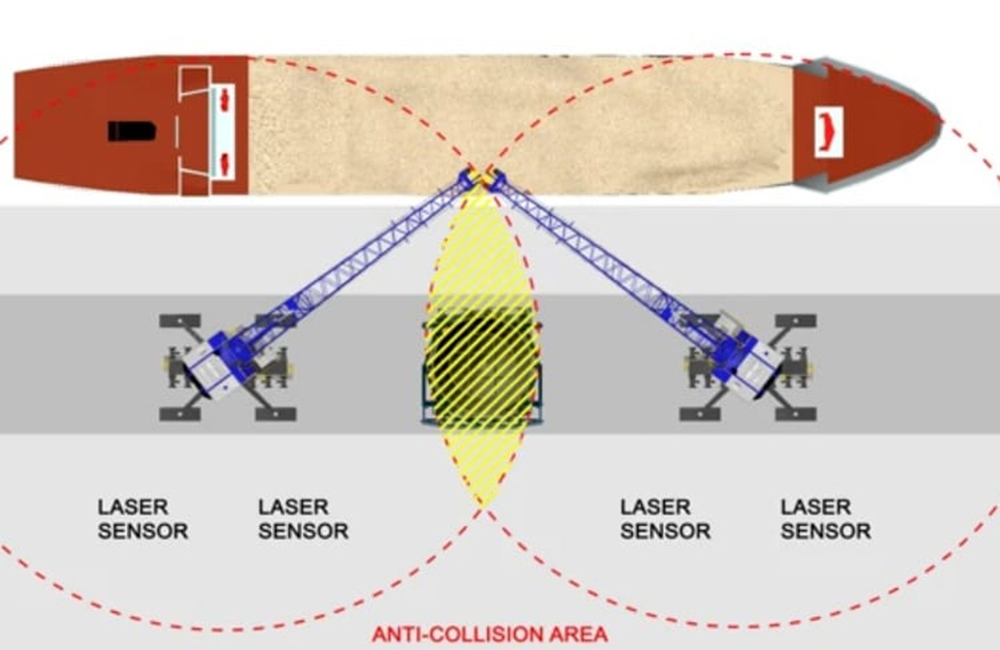

1. MHC multi-machine intelligent and reliable anti-collision warning system

During the joint operation of multiple MHCs, the area amplitude of the anti-collision wall is calculated through calculation. When the sensor at the front of the boom detects an object entering the anti-collision area, the signal will be fed back to the host control system in time, and the control system will give a signal to trigger The sound and light alarm device enters the alarm state.

2. Intelligent path planning system and adaptive control function

The self-adaptive intelligent control function of GENMA MHC grab can automatically control goods with different amplitudes and different densities, flexible selection, and guarantee the maximum grab volume. The grabbed goods will be loaded and unloaded according to the optimized path, which effectively improves work efficiency and reduces the labor intensity of the driver.

3. Intelligent anti-sway system

On traditional jib cranes, swing is inevitable. Swing during the operation will cause the spreader to be unable to locate, reduce the efficiency of loading and unloading, or a little carelessness will cause heavy objects to collide with equipment and personnel, resulting in safety accidents and other problems. After years of repeated tests, GENMA R&D personnel have developed the GILU intelligent anti-sway system, which realizes rapid sway reduction by optimizing the inertia model during cargo operation, thereby improving the stability of operation and the efficiency of container loading and unloading, and effectively improving the efficiency and safety of on-site work coefficient.

4. Intelligent energy storage management

GENMA MHC can automatically recover and store the potential energy generated when the crane is lowered to build a hydraulic energy storage system. The development of this system redefines the energy consumption of the whole machine and the energy saving of the system. Automatically converts potential energy into hydraulic energy, automatically determines how much energy is recovered, and automatically feeds back the absorbed energy. It makes the whole machine achieve the ultimate application in terms of energy use and power consumption, reduces the emission of the whole machine engine per unit time, and is smarter and more environmentally friendly.

Deepen energy saving and emission reduction and promote green development

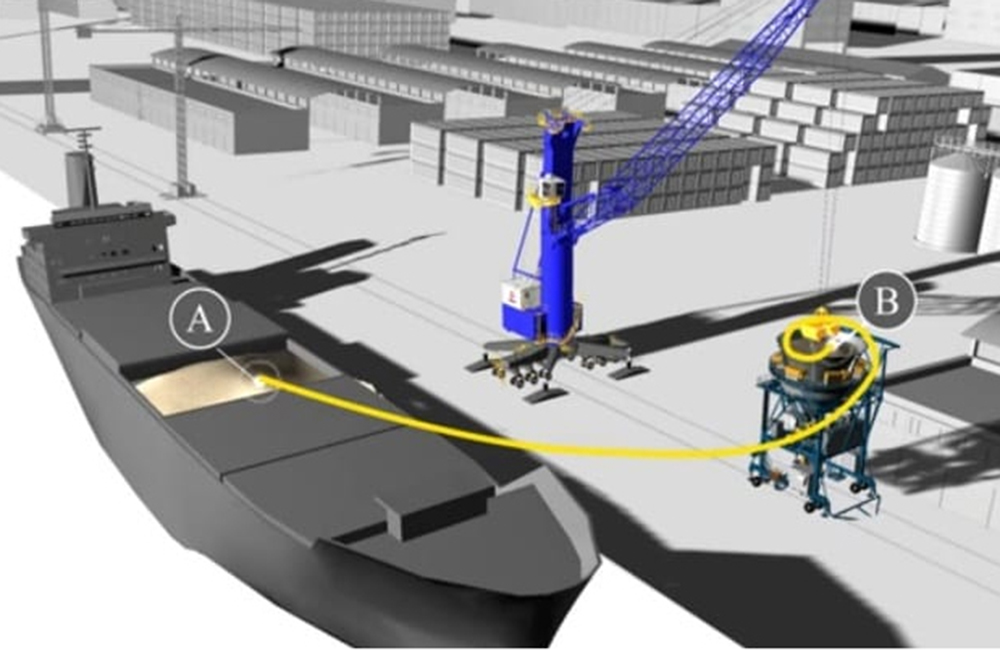

Pneumatic ship unloader is a ship unloading machine that sucks and unloads bulk materials from the cabin by using the negative pressure flow formed by the fan in the pipeline. Various working mechanisms and racks are installed by the suction system and suction nozzles to flexibly suck the materials. And other composition. The GENMA brand ship unloader adopts leading energy-saving and environmental protection technology to effectively solve the problems of energy loss and dust pollution during the operation and operation of the equipment. It is suitable for all kinds of bulk materials, as well as the unloading of power plants, feed factories and aluminum industry materials.

1. Leading fan energy saving technology

Different from the Roots blower technology of other friends, the multi-stage turbo blower technology owned by GENMA can solve the problems of high energy consumption and high noise of traditional pneumatic ship unloaders. Compared with general pneumatic ship unloaders, GENMA ship unloaders can save nearly 30% of energy while ensuring ship unloading efficiency.

2. Self-made dust removal and environmental protection technology

GENMA grain suction machine adopts dust removal technology with independent intellectual property rights and uses a new type of dust suppression hopper to enable the equipment to automatically adapt to the incoming material flow during operation, effectively form a material column, and perfectly solve the pain points of dust spillage. In the process of equipment operation, strictly abide by the national environmental protection management and control standards and meet the requirements of green port construction.

In recent years, the "intelligent manufacturing equipment industry" has been highly valued by the country and the industry. As an international high-end equipment provider, Runbang Heavy Machinery insists on implementing the spirit of the two sessions, taking a new path of intelligent and green development, and creating a new situation for high-quality industrial development. GENMA will also continue to uphold the concept of innovative development, use technological innovation to drive brand development, and use technological upgrades to meet market needs. Under the guidance of the 14th Five-Year Plan of the country, we will strive to achieve more breakthroughs in technological innovation and accelerate the transformation of “Made in China” to “Created in China”. "Upgrade.