At a customer terminal along the coast of China, a GENMA mobile loadeing machine (referred to as loadeding machine) customized by Nantong Rainbow Heavy Machinery Co., Ltd.(short for RHM), is working with two grab door ranes to put into bulk material loading operations with no dust pollution and excellent performance of green environmental protection. The entire production and operation site is neat and orderly, which is particularly clear against the blue sky and sea.

As we all know, bulk materials are prone to generate a lot of dust in the process of loading and unloading. The GENMA mobile oading machine operating site environment is clean and tidy, and each production link is free of dust phenomenon. How does it do that?

"In order to avoid dust pollution in the loading process of bulk materials at port, we independently developed and designed a comprehensive and three-dimensional dust removal system based on the characteristics of bulk material and the key links and mechanisms of dust generation during the equipment operation of in this project, Starting from the source and running the dust removal throughout the entire loading process," GENMA technology research and development personnel introduced.

It is understood that the dust removal system comprehensively uses a variety of dust removal technologies, and forms a green closed-loop control throughout the whole process of bulk loading operation by optimizing the configuration of multiple dust points such as feed port, discharge port, and transfer position of bulk materials.

- At the source

Dust control at source is the core of environmental protection in bulk material loading operations.

GENMA loader hopper adopts octagonal double-layer closed structure design, which can effectively reduce the occurrence of dust caused by excessive bulk material accumulation.

In addition, due to the machine height limitation, the height of the the large hopper baffle wall is low, and the dust above the airtight grille is easy to overflow when the grab is unloading. For this, the equipment hopper is designed with an all-round dust removal device, and the dust removal function of the hopper can be controlled through the remote control. While meeting the loading and unloading requirements of the grab, it also plays a role in suppressing dust pollution from the source.

Effect comparison chart before and after the dust removal function of the hopper is turned on

- In transit

The conveying system adopts a fully sealed design, which can firmly "lock" the dust, reduce the overflow of dust and materials, and change the situation of the coal dust flying in the sky in the past at the bulk cargo terminal.

- In terminal disposal

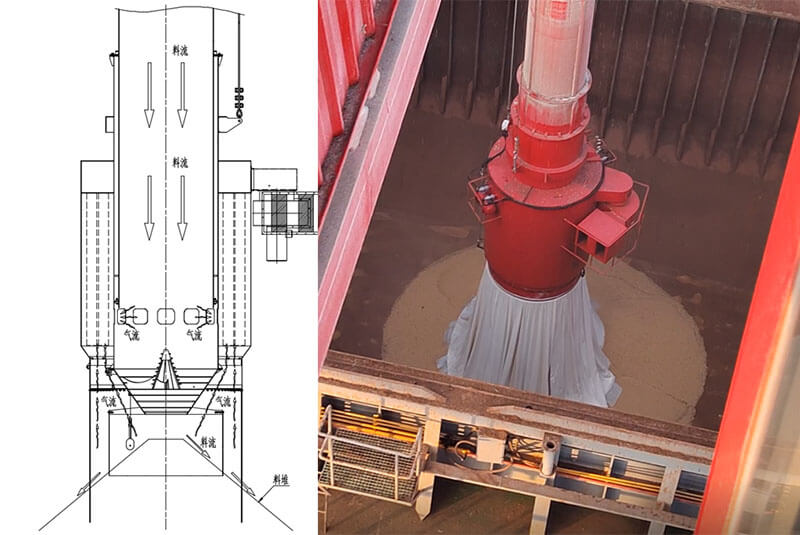

The joints of the telescopic chute joints are sealed and installed, and a buffer device is designed at the outlet below the chute. When the material is transported, the dust suppression system can condense the material into an air-free logistics column,and wrap the fine dust in the center of the material column, thereby achieving the purpose of dust suppression.

At the same time, the discharge port of the chute is equipped with a double-layer annular dust removal device to remove dust from the inside of the cylinder and the outlet below, and strictly control the final pass to minimize dust spillage.

After testing, the GENMA dust removal system can effectively suppress dust pollution such as feeding and discharging, so that each transfer point of the loadeing machine can achieve good dust removal effect and meet environmental protection requirements.

In the field of bulk material handling, the innovative development and application of environmentally friendly technologies is becoming increasingly important. Rainbow Heavy Machinery will continue to give full play to its technological advantages, practice the concept of green development to provide green and environmental protection material handling overall solutions for customers in the port industry.