Recently, Nantong Rainbow Heavy Machineries Co., LTD received a commendatory letters from Brazilian customer PSB (PORTO SUDESTE DO BRASIL S.A.).

The customer stated in the letter that GENMA® MHC would strongly improve the unloading process, reducing the operational downtime, increasing the unloading reliability and growing the business, allowing more vessels with more capacity indeed. They are proud to receive and operate the first GENMA® MHC in Brazil well manufactured and delivered by Rainbow Heavy Machineries.

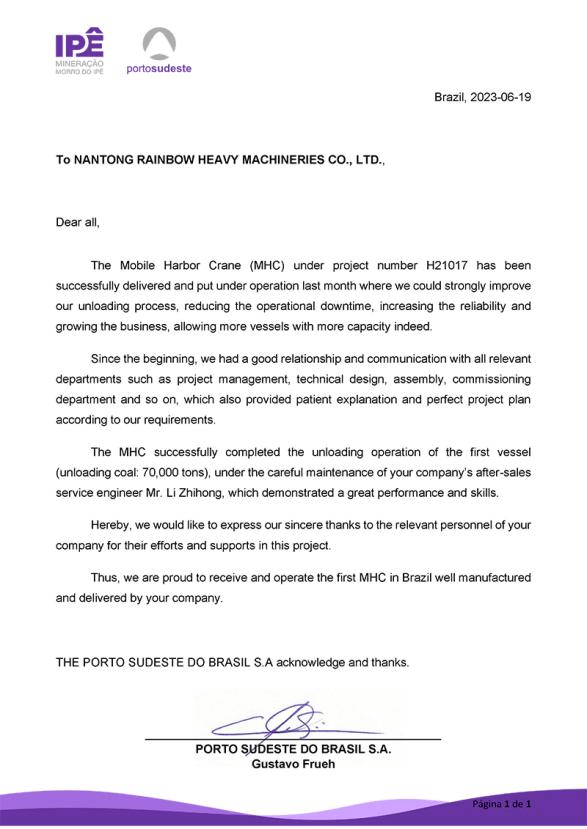

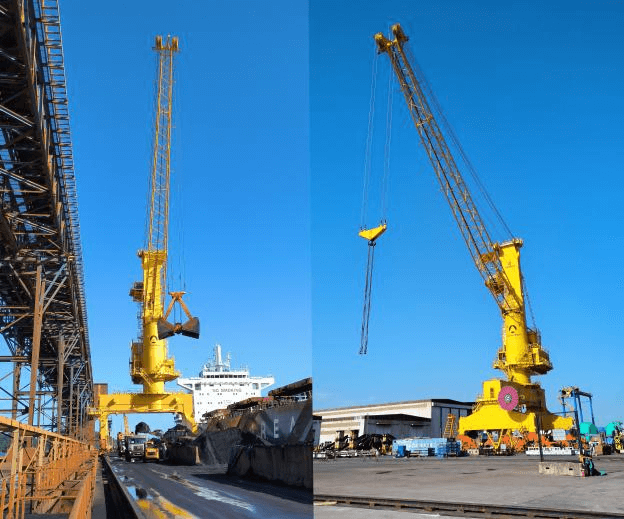

In May this year, a GENMA® 150 ton MHC designed and built by RHM was officially delivered for PSB. The MHC is equipped with two working conditions: hook and grab. Under the hook working condition, the maximum lifting capacity can reach 150 tons; under grab working conditions, the maximum working efficiency can reach 1000 tons/hour. The MHC can simultaneously meet needs of customers for unloading bulk materials such as coal and lifting break bulk cargo.

As of now, GENMA® MHC has successfully unloaded 70000 tons of coal, and had a excellent performance during the operation process. Mr. Gustavo, Business Manager of the client company, praised MHC not only for its exquisite appearance, but also for its reliable performance and excellent efficiency. GENMA® provides professional and high-quality solutions for the lifting and bulk loading and unloading of the terminal.

All along, GENMA®, a brand under RHM, has always been customer-oriented, providing customers with a one-stop solution which included integrates high-end equipment design, R&D, fabrication and service. In addition to meeting the multifunctional needs, efficiency, stability, safety, and environmental protection are also important attributes of GENMA® MHC.

Meet the needs of high-intensity and complex working conditions

The GENMA® MHC delivered to PSB in brazil this time adopts most advanced hydraulic slewing system and hydraulic cylinder luffing system, as well as the latest electric drive dual winch design form, which can ensure stable, reliable, safe and efficient performance of the equipment while fully meeting the customer's high intensity and complex working conditions.

safety and high efficiency, and at the same time, meets the customer's needs for high-intensity and complex working conditions.

“In order to ensure the efficiency of unloading operations, the terminal facilities need to work 24 hours without interruption, with people working in relays, which require high quality of the crane. During the coal unloading process, the GENMA® MHC can work continuously 432 hours, with stable performance and always maintaining high operating efficiency. The quality of GENMA® products is very reliable”

Meet the needs of high economy and environmental protection

In terms of power system, the GENMA® MHC adopts pure electric power configuration for the first time. By using shore based power supply instead of traditional diesel power generation, it has significant advantages in energy conservation and emission reduction.

“This crane is very environmentally friendly, and there is no black smoke or noise at the site. We are very grateful to GENMA® for creating a clean and tidy working environment for us. Mr. Gustavo said that GENMA® MHC meets his expectations for an environmentally friendly crane.”

Meeting the requirements for safe operation

'Safety' has always been an important component of GENMA® brand genes.

To fully ensure the safety of equipment, Designers of GENMA® have focused on optimizing the design of key parts of the crane.

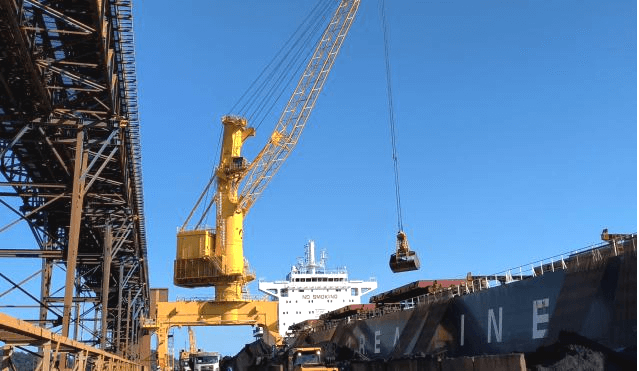

By adjusting the position of the oil cylinder, which designed for supporting the equipment, above the jib, combined with a landing jib design, GENMA® MHC can not only improve the overall structural stress performance and its daily use safety, but also give the ability to flexibly cope with typhoon weather. In addition to the jib design, cab adopts a panoramic window and transparent bottom plate, ensuring that the driver has an excellent panoramic view, which combines convenience, safety, and aesthetics.

It is worth mentioning that the structure, mechanical, electrical, and other aspects of GENMA® MHC are designed in accordance with local safety certification standards in Brazil, and the crane obtains safety certifications such as NR12 in Brazil , This marks that GENMA® MHC safety technology has successfully integrated with the Brazilian market.

In addition to the product itself, GENMA®'s professional after-sales service is also praised by Mr. Gustavo, "After the delivery of the MHC, GENMA® sent the after-sales engineers in time to provide us with professional technical guidance, which makes me feel the professionalism and rigour of GENMA®'s entire service system."

Orientates by customer demand and aims at customer satisfaction, Rainbow Heavy Machineries, as a professional provider of material handling total solution, is committed to providing customized products and services to fully meet our customer’s differentiated needs.

In the future, Rainbow Heavy Machineries will continue to accelerate the pace of internationalization, insist on technology research and innovation, lead by technology and Implement customer-centric approach, continuously exporting " GENMA® solutions" to domestic and foreign customers, and continuously creating value for global customers.