When humans first used stone as a tool, design began. In fact, real industrial design began with the first industrial revolution. In the 250-year history of human industrial design, countless outstanding industrial products have been born.

For example, mobile port cranes.

(世界上第一台蒸汽起重机) (现代化的移动式港口起重机)

Mobile port cranes, commonly known as dock overhead cranes, are referred to as MHC.

This kind of port machinery, not to mention ordinary people, even port people, don’t know much. So far, it has only 4 brands in the world, 3 in Western countries and 1 in China.

The MHC produced in China comes from Runbang Heavy Machinery, and the brand is Genma/GENMA.

First look at a few work photos:

Mobile port cranes can load and unload a variety of cargo including containers, LNG tanks, general cargo, timber, coal and other bulk materials. They are called "port all-rounders" and are welcomed by comprehensive terminals.

Of course, today we are not a popular science machine, but through its details, we understand the industrial design concept presented by the domestic port machinery.

1. Multi-tyre design

We have seen a lot of machines with multiple tires, but we must rarely see a port machine with so many tires, right?

As shown in the picture above, this MHC has 20 tires and the number of tires has reached 80.

Of course, so many tires are not designed to be spectacular.

why?

Don't worry, look down.

Everyone wants to use good machines, but not all terminals have good terminal infrastructure such as SIPG and Shenzhen Port, and many old terminals do not meet the standard load-bearing capacity.

In order to reduce the pressure of the machine on the wharf ground, GENMA MHC will design different numbers of tire schemes according to the carrying capacity of the wharf to evenly share the weight of the machine and reduce the cost of wharf renovation.

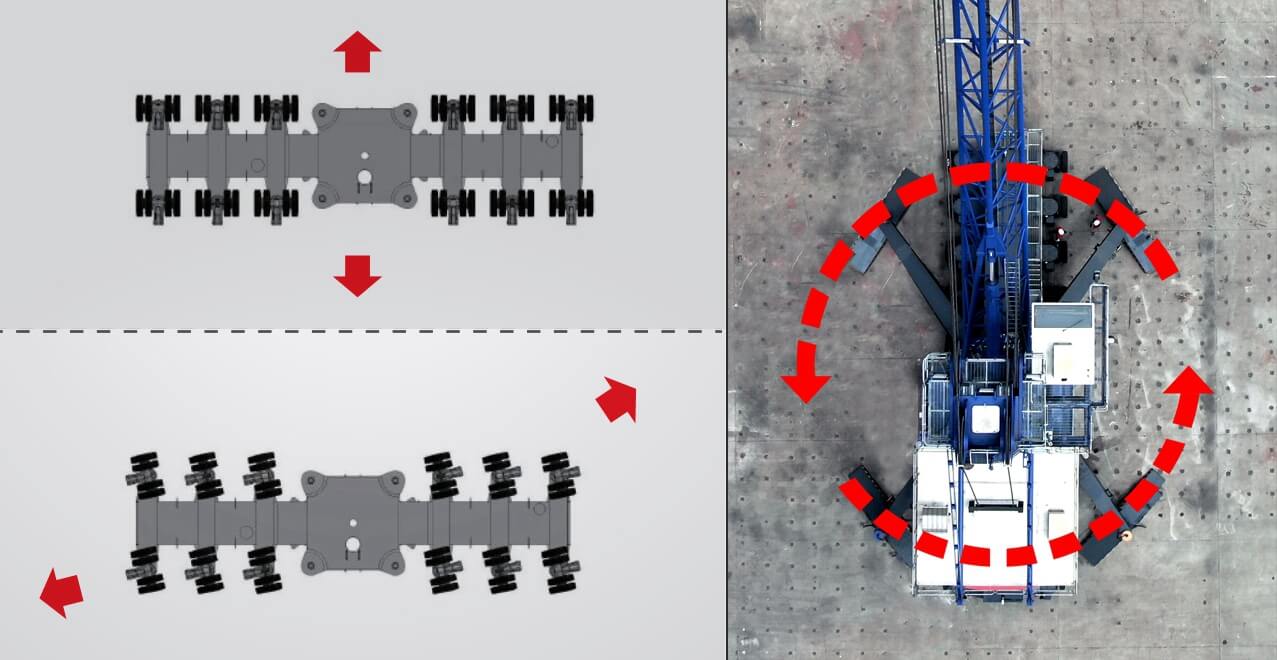

2. Full-angle walking design

"Surely this behemoth must be awkward to move, right?"

If you ask like this, you can only say that you don’t know anything about "flexible fat guys", just look at the picture:

In the process of moving, GENMA MHC not only can go straight and back, but also has the function of lateral and oblique driving at any angle. When necessary, it can also perform a 360-degree "Thomas maneuver".

To put it bluntly, it means where to open.

This design allows GENMA MHC to have good passability and is suitable for piers with narrow and irregular terrain.

3. Design of landable boom

The boom of GENMA MHC can be dropped to the ground in typhoon weather, ensuring the safety of the machine. At the same time, this floor-standing design makes maintenance of the boom more convenient.

It is worth mentioning that the cylinder of GENMA MHC supporting the boom is designed above the boom.

This design makes the force form of the oil cylinder more reasonable, and most importantly, it can effectively avoid the collision between the cargo and the oil cylinder.

This kind of design seems to be a simple position adjustment, but at a deep level, it is an industrial design thinking from the perspective of the customer.

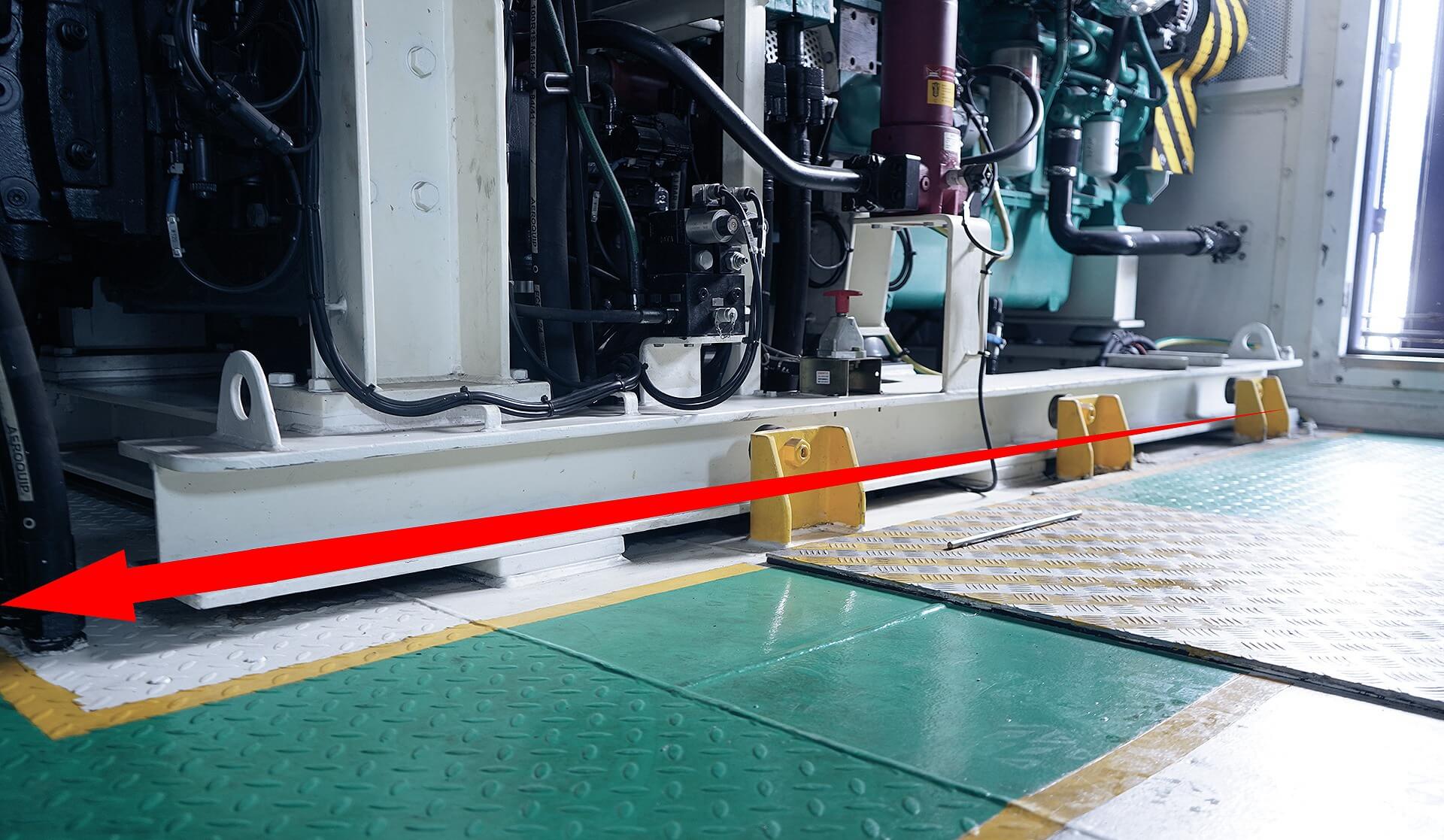

4. The design of the moving track of the engine

The engine is the heart of the machine. What if the heart is going to be operated and the "scalpel" outside cannot get in?

GENMA designed a sliding track for the engine. When maintenance is needed, the engine can be easily slid out of the machine compartment, making subsequent maintenance more convenient.

5. Safe fueling control design

Some time ago, the news reported that the MHC of a foreign brand caught fire again...

It is understood that this is a spontaneous combustion accident caused by staff filling fuel when the machine is not stalled.

There are always unruly people in the world who are greedy for convenience and operate illegally. It is obviously unrealistic to hope that people will consciously abide by the operating procedures.

How to do?

GENMA designers designed a safety refueling system for MHC. This system can ensure that when the staff fills the fuel, there will be no spontaneous combustion accidents.

6. Elevator design

This design is more common in some ultra-high cranes, but the application of high-level machines like portal cranes is relatively rare.

From a "people-oriented" perspective, GENMA has added elevator design to the interior of the new generation of MHC tower, which has to be said to be a benefit for workers.

7. Other stunning detail designs

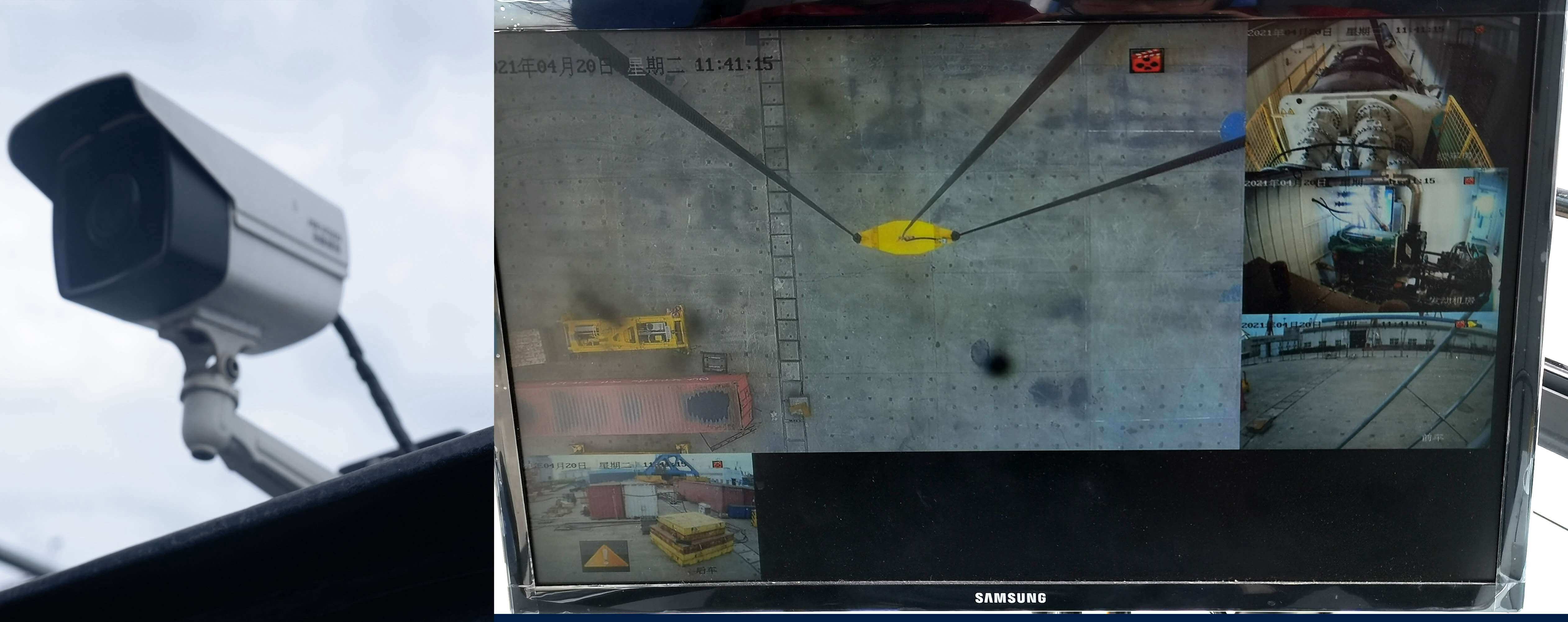

(1) Vertical ground observation window

The GENMA MHC cab is designed with a 180-degree panoramic window, and video surveillance is installed in key areas of the machine.

Do you think this is over?

GENMA MHC even opened a window on the floor, and the driver can see the vertical ground when he turns his head. This design is really amazing.

(2) Instant messaging system

This instant messaging system is distributed in the main parts of the machine.

In case the driver’s cell phone or walkie-talkie is out of power or the signal is bad, he can pick up the instant phone at hand to contact him at any time.

(3) Wire rope roller

GENMA MHC wire rope pulley is made of nylon.

So, why not use steel?

This is the meticulous industrial design thinking of GENMA engineers. If a steel pulley is used, the wire rope and the pulley will have to be "hard", which will accelerate the wear of the wire rope and reduce its service life.

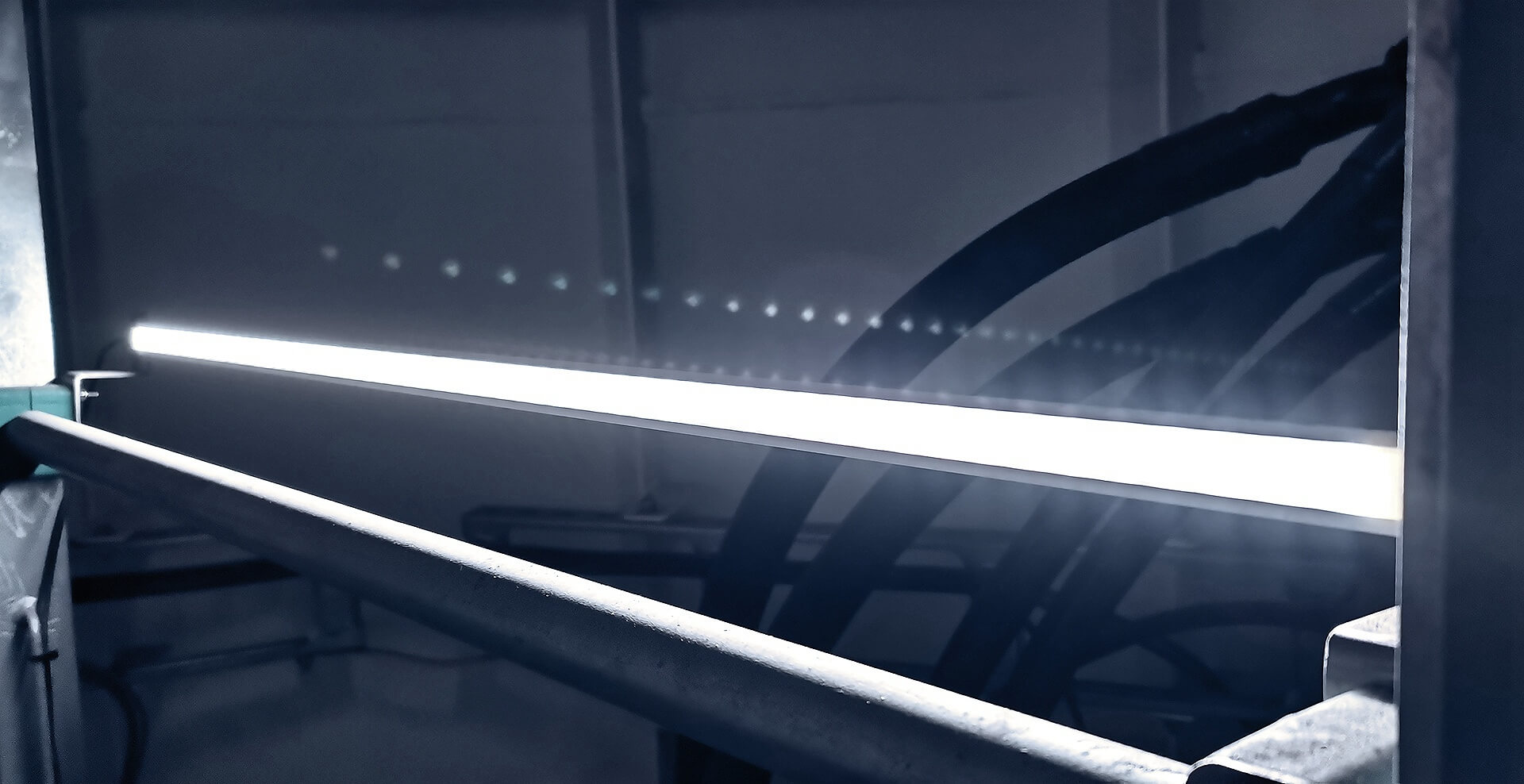

(4) Night lighting belt

This LED light strip design makes the machine very dazzling at night.

If you think this is purely for aesthetics, then the engineers at GENMA are too superficial.

This 24V DC-powered waterproof floodlight is moisture-proof and explosion-proof, and has a wide range of lighting. It can be installed in areas such as electrical rooms, machine rooms, and walkways, which improves the efficiency of night operations.

(5) Machine wiring

This industrialized wiring design can definitely cure many patients with obsessive-compulsive disorder, right?

(6) Multimedia broadcasting system

The GENMA MHC cab is equipped with a multimedia broadcasting system, so that the driver can transmit various information to the outside of the machine at any time.

The cab is designed with sound-proof glass to create a quiet working environment for the interior. It is also equipped with a high-quality sound system, first aid kit, etc. These small details are the demonstration of GENMA's industrial design concept.

The above is just the most superficial design of GENMA MHC, and there are many core design technologies, which can be seen from the current 30 patents related to MHC.

One thousand words, ten thousand words, excellent industrial design, the essence of which is to make the product more usable, more practical, and more efficient. From this perspective, the industrial design of GENMA MHC is undoubtedly outstanding.

Finally, attach an egg:

Do you know what the MHC driver's cab is doing?