Due to the particularity of the material, the dust pollution during the loading and unloading process of bulk cement has always been a pain point in the operation of the cement terminal. The usual treatment methods are to use water trucks, dust removal fog guns, improve dock greening, and even increase the number of dock sanitation workers, but these symptoms do not cure the root cause. The key link in dust control is dust suppression. Only by solving the dust leakage of cement in the process of unloading and transportation, can the problem of on-site dust pollution be fundamentally solved.

The key to solving dust leakage lies in the dust suppression ability of cement unloading and conveying equipment. As a professional bulk material handling and conveying solution provider, Runbang Heavy Machinery has conducted a lot of research in the field of bulk cement handling and conveying. At present, the two brand products launched by Runbang Heavy Machinery can solve the problem of flying dust in cement terminal operations with high quality.

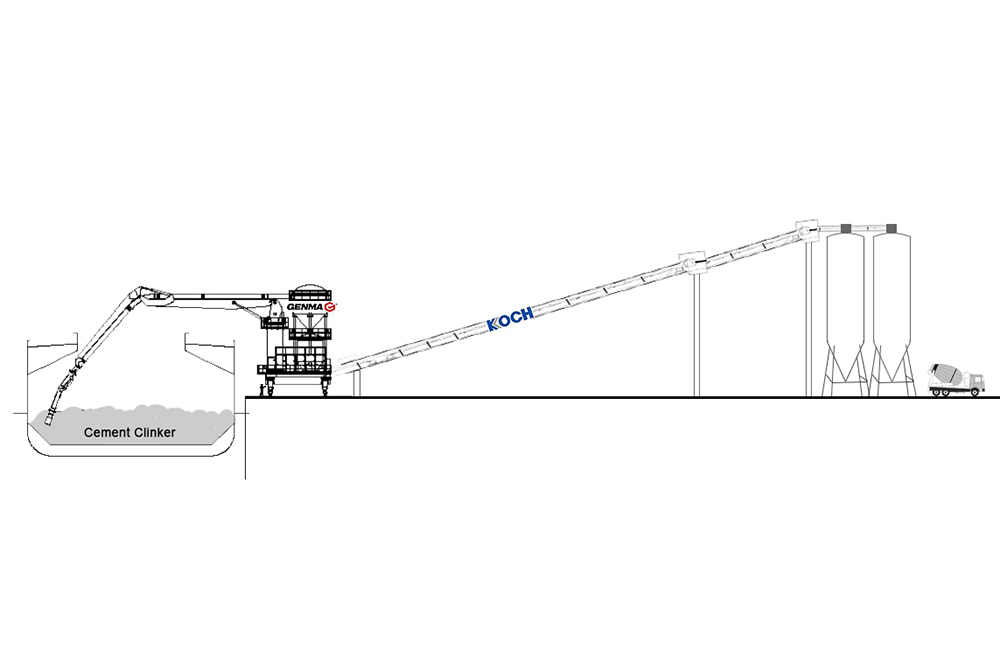

1. GENMA brand cement pneumatic ship unloader

GENMA brand cement pneumatic ship unloader (hereinafter referred to as GENMA ship unloader) is a bulk cement loading and unloading equipment specially developed by Runbang Heavy Machinery for cement terminals. The maximum unloading capacity is 600 tons/hour, and the maximum application ship type is 60,000 DWT, which can be based on the actual situation of the terminal. The situation is designed to be fixed, track or tire.

GENMA has been committed to the research of dust control technology for a long time, and has formulated corresponding solutions according to the characteristics of different bulk materials to effectively solve the problem of dust pollution during continuous bulk material unloading.

So, what are the advantages of GENMA products compared with general pneumatic ship unloaders?

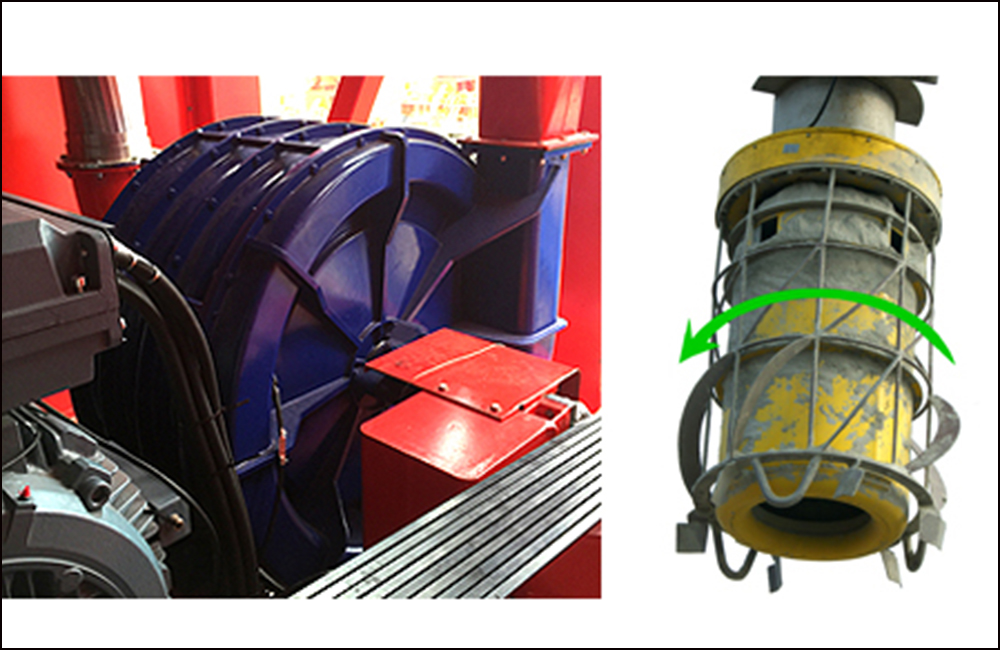

1. Unique design of dust collector-the size of the mechanism is reduced by 40%, and the dust leakage rate is 0

The GENMA ship unloader adopts a unique dust removal cartridge design, which combines gravity separation and filter bag separation technology, which greatly reduces the size of the dust removal mechanism, reduces the burden on the filter element, and improves the efficiency of dust removal. The entire dust removal process of the GENMA ship unloader is fully enclosed to ensure that there is no leakage of cement dust.

2. Pleated filter bag design-the dust filter area is increased by 2 times

Under the same filter cartridge diameter, the GENMA ship unloader adopts a pleated filter bag design, which increases the filter area by more than 2 times, improves the dust removal effect, reduces the volume of the filter bag, and effectively reduces operating energy consumption, pre-production costs and post-production The maintenance fee is also reduced accordingly. In addition, the GENMA ship unloader adopts a new type of filter cloth bag, which reduces the filter pressure loss and has a better dust removal effect.

3. Multi-stage turbo fan technology-saving energy consumption by 30%

The multi-stage turbofan technology owned by GENMA has always been ahead of the Roots fan technology of other partners. This technology solves the problems of high energy consumption and high noise of traditional pneumatic ship unloaders. Compared with general pneumatic ship unloaders, GENMA ship unloaders can save nearly 30% of energy, and its super adsorption force greatly improves the efficiency of ship unloading.

In recent years, with the continuous update and iteration of GENMA technology, the permanent magnet motor-driven fan technology has improved the operating efficiency of the GENMA ship unloader and further reduced the energy consumption of the entire machine.

4. Flexible boom design-25% reduction in clearance volume

A large part of the ship unloading operation at the dock is spent cleaning up residual materials. In this regard, the GENMA ship unloader adopts a four-section hydraulic tilting boom design, which is flexible and efficient. With the new rotary power suction nozzle, it can effectively absorb the residual cement in the dead corners of the cabin. Reduce clearance volume and reduce terminal operating costs.

2. KOCH brand tubular belt conveyor system

The KOCH brand tubular belt conveyor system (hereinafter referred to as the KOCH conveyor) is an equipment developed by the German KOCH company under Runbang Heavy Machinery for conveying various bulk materials (almost all bulk materials such as cement, magnesium powder, and grain). The maximum conveying capacity is It is 8000 tons/hour, and the maximum conveying distance of a single machine is 8.2 kilometers.

KOCH has extensive experience in the field of bulk material transportation. Since 1985, KOCH has installed more than 350 sleeve belt conveyors in more than 40 countries and regions. At present, there is no tubular belt conveyor in the world that can fully and extensively realize installed applications and production operations like KOCH.

Compared with ordinary belt conveyors, KOCH has obvious advantages:

1. Design of fully enclosed conveying space-0 cement dust pollution along the way

The KOCH conveyor adopts a fully enclosed design, which is extremely environmentally friendly, avoids dust pollution and leakage waste during the conveying process of cement, and also prevents the conveyed materials from being rained. At the same time, it has the characteristics of low noise and no disturbance to the people. . KOCH conveyors can cross roads, railways, waterways, as well as existing factories, public streets, and even environmental protection areas.

2. Breaking through the transportation limit-8.2 kilometers ultra-long transportation distance

The KOCH conveyor has a maximum axial conveying distance of 8.2 kilometers, can turn in three dimensions, does not require a transfer station, and the loading belt and return belt can convey different types of materials at the same time, and multiple feeding points can be set.

3. More flexible small space conveying design-save 60% of space

Regardless of the site conditions, KOCH can minimize the transportation distance, from the bulk material terminal to the cement plant, to achieve the highest cost-effective production line layout. Compared with traditional belt conveyors, the KOCH passing area can reduce the occupied space by 60%.

4. All-terrain adaptive design-more than 190 successful cases of complex terrain

KOCH has more than 190 successful cases in complex terrain and has rich experience in customized design. These bulk material conveying systems used in the Gobi, hilly, and dangerous shoal terrains have been in stable operation, verifying KOCH's leading bulk conveying technology.

The application of the KOCH tubular belt conveyor in the Malaysian cement plant is extremely successful: the cement is transported to the ship loading station on the sea, and the cement will not be affected by high humidity. Since 1995, the system has proven highly reliable and can operate under extreme conditions.

In summary, the GENMA cement pneumatic ship unloader and the KOCH tubular belt conveyor system can be seamlessly connected. The two sets of equipment are used together to ensure that the cement will not be unloaded and transported from the transport ship to the terminal site. Dust pollution is the best solution for building a modern green terminal.

![]()

GENMA brand cement pneumatic ship unloader and more port machinery products

Overseas market\Central China market:

Mr. Zhang / +86-135-8584-7578 / Lei.zhang@rainbowco.com.cn

South China\North China\East China Market:

Mr. Li /+86-136-4628-7877 / Roger.lee@rainbowco.com.cn

![]()

KOCH brand tubular belt conveyor system

Greater China market:

Mr. Qian / +86-158-2166-4561 / Bill.qian@rainbowco.com.cn

Adhering to innovative technology to create value for customers

www.genmasolution.com

![]()

Welcome to follow GENMA social media to learn about the latest information on GENMA material handling technology