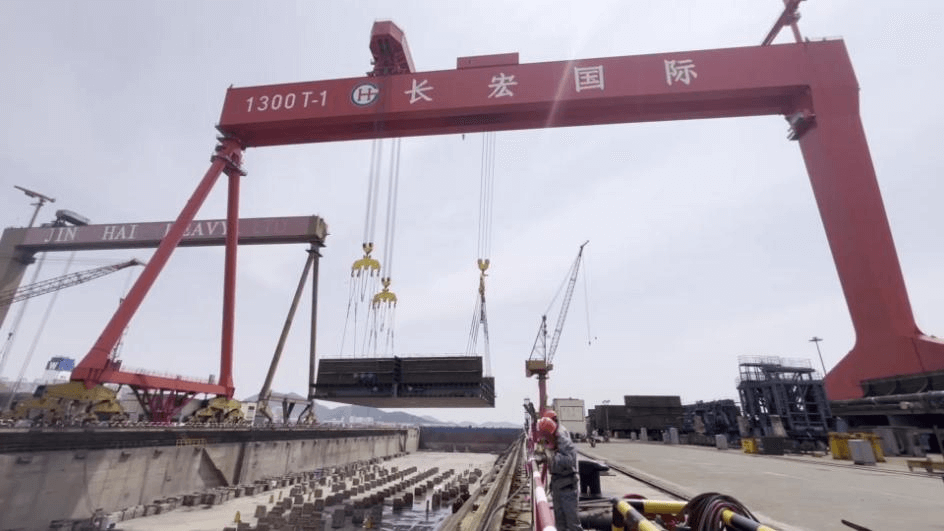

GENMA 1,300-ton Gantry Crane Debuts with Success, Lifting Multiple Large Ship Sections

Recently, GENMA’s 1,300-ton × 146-meter ultra-large double-girder gantry crane (referred to as gantry crane) completed its debut lifting operation with precise and efficient performance.

During the debut, the GENMA 1,300-ton gantry crane successively executed lifting, moving, and positioning of ship sections weighing 741 tons, 703 tons, and 341 tons, along with flipping a 229-ton section. The equipment operated stably throughout, demonstrating exceptional positioning accuracy and showcasing GENMA’s technical prowess in large-scale, intelligent lifting solutions.

This gantry crane features an intelligent control system equipped with anti-sway technology and real-time monitoring, significantly enhancing lifting precision and operational safety. It is particularly suited for assembling large structural components like ships. The crane’s power system utilizes regenerative feedback technology, converting gravitational potential energy during operation into reusable electricity, enabling energy-efficient and eco-friendly performance while reducing operational costs.

As the first gantry crane GENMA delivered to this client, a second unit of the same specification is currently in final assembly. Both cranes were manufactured by Nantong Rainbow Heavy Machineries Co., Ltd.

During the debut, the GENMA 1,300-ton gantry crane successively executed lifting, moving, and positioning of ship sections weighing 741 tons, 703 tons, and 341 tons, along with flipping a 229-ton section. The equipment operated stably throughout, demonstrating exceptional positioning accuracy and showcasing GENMA’s technical prowess in large-scale, intelligent lifting solutions.

This gantry crane features an intelligent control system equipped with anti-sway technology and real-time monitoring, significantly enhancing lifting precision and operational safety. It is particularly suited for assembling large structural components like ships. The crane’s power system utilizes regenerative feedback technology, converting gravitational potential energy during operation into reusable electricity, enabling energy-efficient and eco-friendly performance while reducing operational costs.

As the first gantry crane GENMA delivered to this client, a second unit of the same specification is currently in final assembly. Both cranes were manufactured by Nantong Rainbow Heavy Machineries Co., Ltd.

Moving forward, GENMA will continue to provide reliable products and customized services, delivering smarter, more efficient material handling solutions for industrial clients worldwide.