New generation of mobile harbour crane features intelligent technology to increase unloading efficiency and a new choice of under carriage.

Genma is a brand of Rainbow Heavy Industries (RHI) and builds its mobile harbour cranes at the company’s base in Nantong, China. RHI entered the mobile harbour crane market in 2016, and has now launched its 3rd generation product.

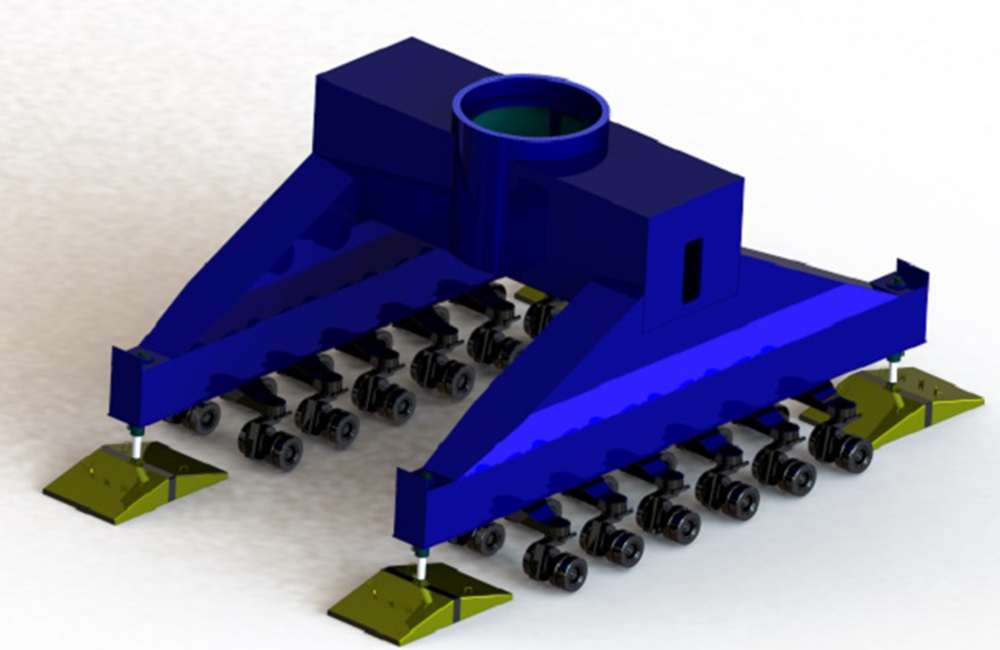

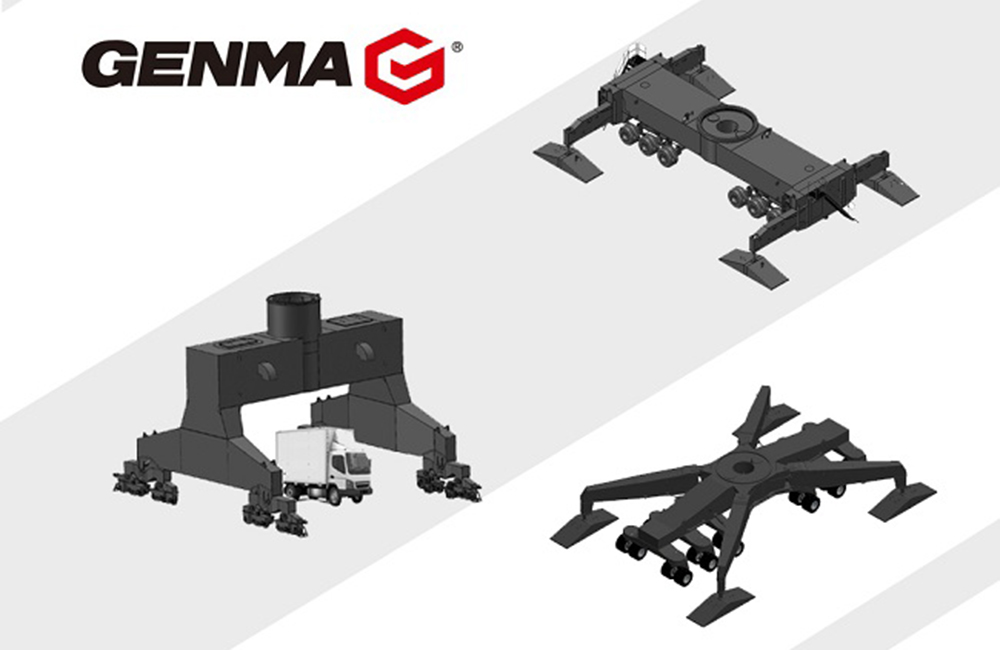

New features include an upgraded tower structure, that the company says is stronger and more reliable, and a new choice of undercarriage featuring a portal mounted on rubber tyres to add to the existing three undercarriage options. The portal, Genma adds, means the crane can work over railway wagons, and the rubber tyres increase flexibility to move the crane between berths.

As well as the new options, Genma claims the 3rd Generation series are 20% more efficient than its previous models. This is achieved through a new “Intelligent Loading & Unloading System” that can follow a predetermined optimal load path after two manual cycles to set the initial and destination working points. Genma adds that the system is simple to use and requires no complex operator training.

In addition Genma has improved its anti sway system to increase performance and reliability, and in particular to make container operations smoother. “This also means that more time is saved and the efficiency is greatly improved and the fatigue of operators is reduced,” Genma notes.

For grab operations, Genma has developed “Intelligent Grabbing Technology” that can adapt to a variety of materials, while at the same time maximising the grab load and optimising the grab cycle.

For handling project cargo and heavy lifts, Genma has introduced a “Multi machine cooperative operating system” that lets one operator control two cranes simultaneously, as well as utilising the full maximum lifting capacity of both cranes.

On the environmental side, to improve the environmental performance of its mobile harbour cranes, the 3rd Generation includes options for shore power and a hydraulic accumulator that can store energy, something the company notes is new technology for Genma.