At the new product launch conference of Jiangsu Rainbow Heavy Industries Co ., Ltd. held on December 10, the sub-brand GENMA demonstrated 8 new technologies successfully developed this year. These technologies are mainly used in material handling equipment, which perfectly interprets GENMA's characteristics of high efficiency, energy saving, environmental protection and intelligence.

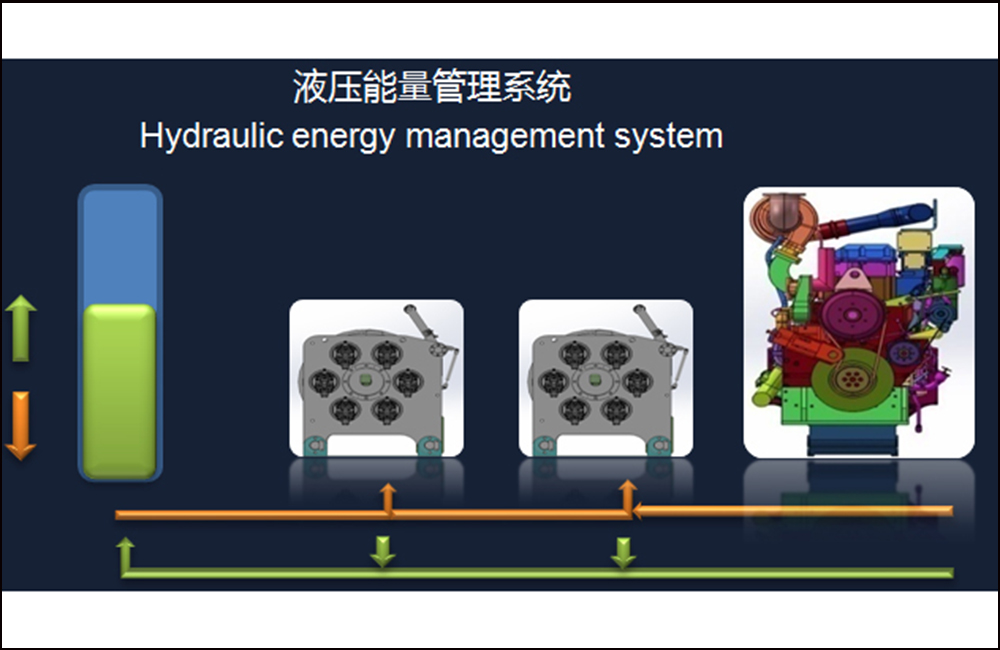

1、Energy management technology

The technology uses the engine power balance and hydraulic energy management system to manage, store and utilize the peak and valley energy of the product in different working conditions, which can not only effectively reduce the installed power, but also improve the working efficiency.

For the product with electric drive, the use of energy management technology can effectively suppress the impact of harmonics generated by the drive on the power grid, increase the power factorto 1, and the braking energy can be fed back to the power grid and fully utilized.

At present, this technology has begun to be applied to GENMA mobile harbor cranes and portal cranes.

2、Dust control technology

This technology is mainly used for dust suppression during bulk material unloading and ship unloading operations, and effectively reduces dust pollution in ports, yards and other places.

GENMA product r&d personnel have developed a new type of dual-spool dust suppression hopper, which enables the equipment to automatically adapt to the incoming material flow during operation, effectively form a material column, and perfectly solve the difficulty of dust overflow.

In the working conditions of the hopper, GENMA reasonably optimized the high-pressure spray system and the dry mist dust suppression system according to the operating characteristics. Through the ingenious arrangement of spray points and multi-mode working condition control, the energy consumption of dust suppression system is reduced on the basis of maximizing dust suppression control.

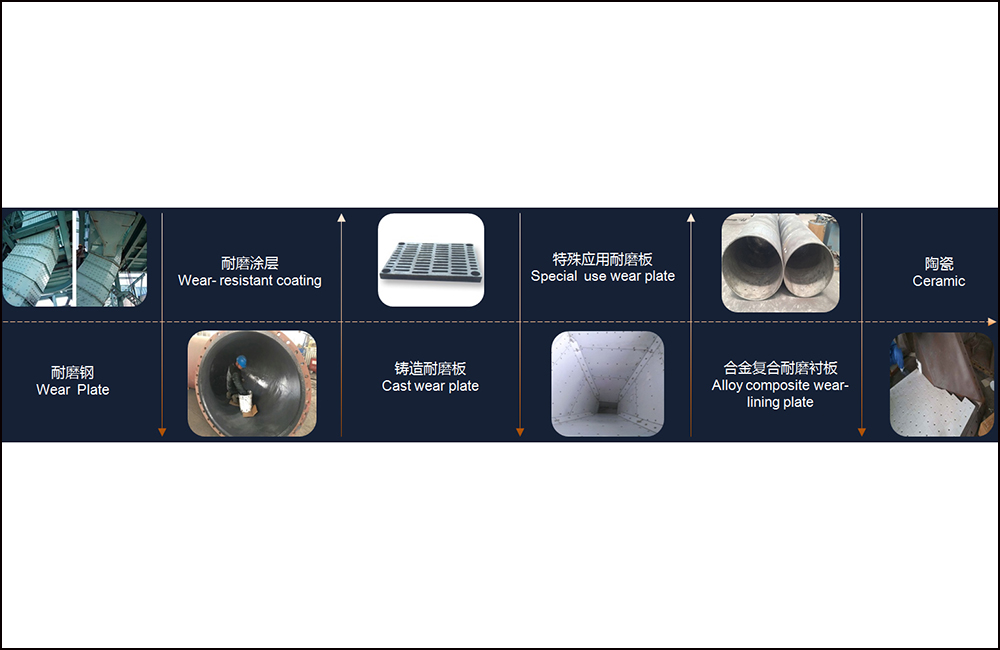

3、Wear-resistant application technology

Based on the characteristics of bulk material conveying, combined with advanced simulation technology, GENMA accurately simulates the flow direction, speed, and impact value of the material. Through the selection of different wear-resistant materials, the targeted design realizes the controllable life of the key wear-resistant parts, which greatly improves the service life of the equipment and reduces the maintenance rate.

At present, this technology has been applied to the design of all GENMA bulk material conveying equipment.

4、Adaptive control technology of suction nozzle

The suction of negative pressure pneumatic conveying in general pneumatic ship unloader is easy to cause unstable operation due to uncontrollable suction nozzle state. GENMA R&D personnel feed back the read current of the drive motor to the control, and adjust the reclaiming depth and air supplement in time to keep the fan in a high-efficiency and stable operating state.

At the same time, the technology can reduce the downtime caused by man-made factors through the automatic adjustment of the tuyere, improve the stability of the operation, increase the operation efficiency, and reduce the operation energy consumption.

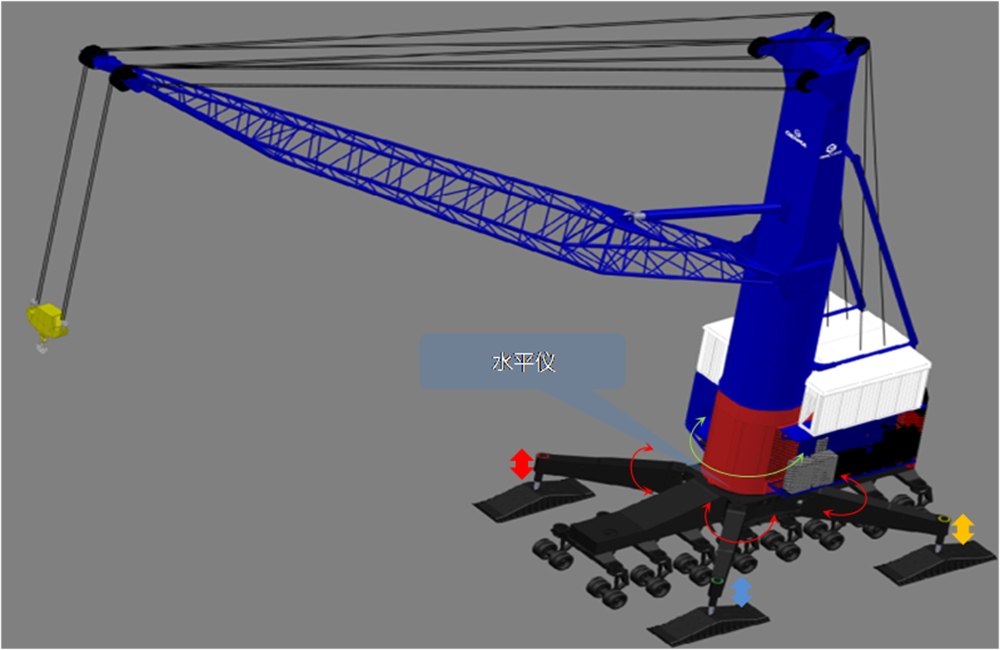

5、One-click off-running

Through an excellent ergonomics system, this technology realizes the vertical cylinder rising of the machine outrigger and the horizontal cylinder retraction of the outrigger by one click, which automatically transforms the MHC from travelling state to shutdown state, which increases the safety of equipment operation and reduces the labor intensity of the personnel.

At present, this technology has been fully applied to GENMA Mobile Harbor Crane (MHC), effectively improving the automation level of the equipment.

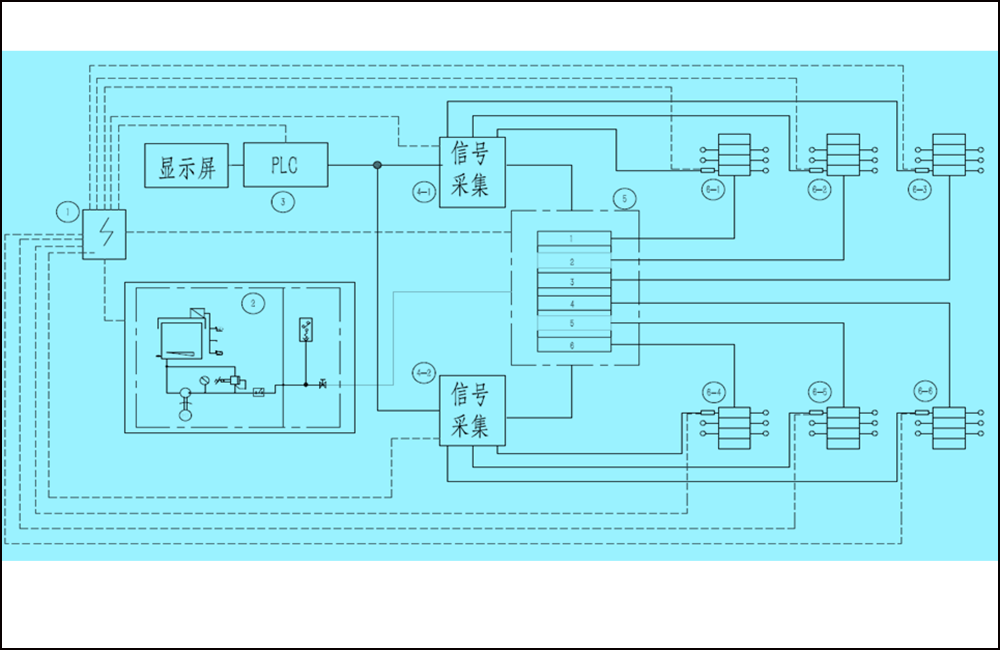

6、Intelligent lubrication technology

This technology uses PLC to control the intelligent oil separator to supply oil regularly and quantitatively to different motion frequency areas, control the oil output of the oil separator. It can also realize the monitoring of the status of each lubricating point in the process, reduce the manual maintenance intensity and product maintenance cost, and prolong the service life of the machine.

At present, this technology can be applied to various port machineries, portal cranes, gantry cranes and other equipment according to customer needs.

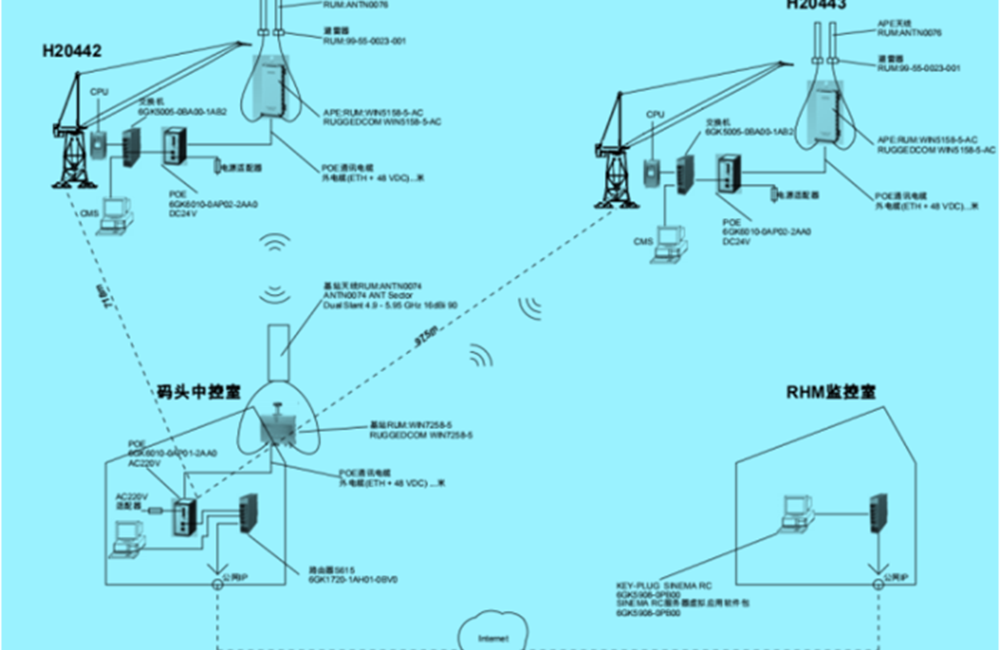

7、RCMS technology

This technology uses the industrial Internet of Things to realize remote connection of equipment through wired or wireless networks, and real-time understanding of machine operating status, work efficiency, energy consumption and maintenance information.

At the same time, the technology can also browse field equipment through remote Web, and query information such as metering, efficiency, failure, and maintenance cycle. Commissioning and maintenance personnel remotely connect PLC and HMI to upload and download programs and perform online fault diagnosis to reduce downtime for maintenance. And lay a good technical foundation for future remote control.

This technology has been applied to the products such as harbor crane MHC, portal crane, gantry crane, offshore crane, pneumatic ship unloader, grab ship unloader, and ship loader.

8、Intelligent monitoring technology

This technology uses sensor technology and intelligent analysis software to form an equipment condition monitoring system, which effectively monitors machine vibration, bearing damage, gearbox wear, motor bolt looseness, stator failure and other information, and analyzes early diagnosis and warning of mechanical damage through trend curves.

After the application of intelligent monitoring technology, it can immediately monitor the operating status of key parts of the equipment, perform preventive maintenance and repair, find and repair early, extend the service life of the equipment, reduce downtime, and improve the stability and reliability of this type of product.

Director Cui of the R&D Department also stated at the new product launch conference that GENMA will continue to carry out standardized design of products in the future, strengthen the R&D efforts of the products in terms of energy saving, consumption reduction and environmental protection, so that the industrial design of each product can meet the requirements of customers, and continue to provide professional ports, storage yards, and intelligent solutions for customers.