Recently, a GENMA mobile ship loader and two grab gantry cranes are working together on the load-reducing platform of a customer's wharf along the coast to continuously transfer the bulk cargo on the cargo ship to the empty ship on the other side of the wharf. In the cabin, a new mode of "water-water transfer" operation at the customer's wharf was successfully launched.

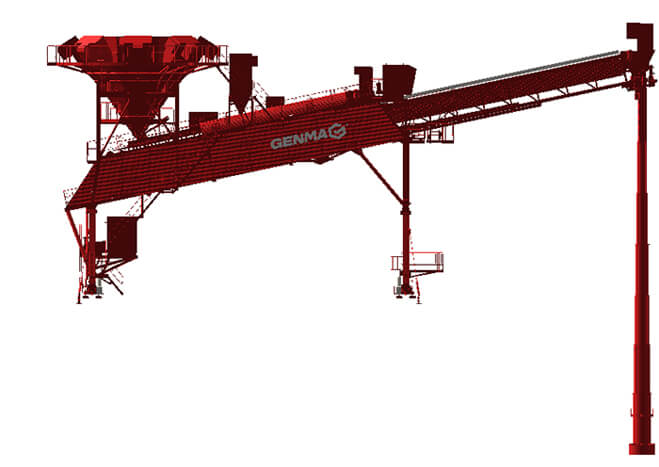

Ship loader is a large-scale port machinery equipment, which is mainly used for continuous ship loading of bulk and bagged materials.

The GENMA mobile ship loader (referred to as: ship loader) put into use this time is customized and built by RHM for the customer company. The rated operating efficiency of this equipment is 1,200 tons/hour, which can realize the "water-water transfer" loading operation of bulk carriers with a deadweight of 50,000-200,000 tons at the front berth and a bulk carrier with a deadweight of 2,000-20,000 tons at the rear berth. Together with vehicle traveling device, the equipment can be moved and positioned along the ground track to realize flexible and efficient loading operations at each berth of the wharf.

From the overall appearance of the equipment, it is not difficult to see that the ship loader has a unique and novel shape. In addition to the conventional belt conveyor, telescopic chute and telescopic boom system, its tail is also equipped with a large dust removal hopper device. During the operation, the crane grab only needs to unload the material into the large dust removal hopper, and the material can be transferred to the cargo ship cabin through the belt conveyor system and the telescopic chute on the ship loader, accomplishing a complete set of "water-water transfer" operation process.

In addition to customizing the design of the product structure system according to customer needs, GENMA product designers have also made many detailed layouts for the practical functions of the equipment according to the actual usage scenarios.

- The design of the extended telescopic chute adapts to a variety of working conditions

In order to meet the needs of ships with large drop between deep tanks and cabins and bulk material loading under different tides, and improve the efficiency of loading operations, the telescopic chute of the GENMA ship loader adopts a lengthened design, and the telescopic distance of the chute is up to 23 meters (equivalent to the height of 7 floors), reaching the domestic leading level.

The equipment chute can be telescopically adjusted according to different water levels and the fullness of the tank, so that the ship can be loaded more accurately and efficiently, and at the same time, by controlling the blanking height, dust flying at the blanking point is suppressed.

In addition, the chute of the equipment is also designed with an automatic retraction function. When the material under the chute accumulates to a certain height, the "small mechanism" of the chute blanking port will be triggered, and the chute will automatically retract. The ingenious design in the details can not only effectively avoid the material blockage caused by the accumulation and retention of materials in the discharge port, ensure the operation efficiency and stability, but also reduce the labor intensity and improve the intelligence level of unloading operations as a result of automation procedures.

- lCombined dust suppression device to meet the requirements of terminal environmental protection operations

In view of the fact that the cement clinker loading and unloading operation is easy to raise dust, GENMA adopts a variety of combined dust suppression methods, and takes special treatment for each dust raising point.

Feed inlet: The hopper device adopts a double-layer closed structure design and is equipped with an all-round dust removal device, which can suppress dust pollution from the source while meeting the requirements of grab loading and unloading.

Outlet: A sealing device is designed and installed at the joint of the telescopic chute, which can effectively avoid dust spillage, improve the environmental protection of the operation, and improve the quality of bulk material loading; the chute outlet is equipped with a double-layer dust removal device, in a bid to maximize the control of dust spillage.

As a modern green collection and distribution method, "water-water transfer" is efficient, environmentally friendly, time-saving and labor-saving. It is conducive to resolving urban traffic congestion and environmental pollution problems caused by highway transfer, effectively improving the timeliness and economy of cargo transportation, and strengthen the deep integration of port logistics and inland logistics.

RHM has been working in the field of port machinery for more than a decade, focusing on providing customers with various port loading and unloading equipment. In the context of the world's green and low-carbon development and transformation, RHM will continue to pay attention to market demands such as efficient production and environmental protection, and create a new blueprint for green and sustainable development for ports and enterprises with customized solutions and services.