In the remote port of Acajutla, El Salvador, two GENMA mobile harbor cranes (MHC) are extending their long booms, lightly transferring containers from cargo ships to terminal trucks, lifting, translating, landing, and loading, the whole loading and unloading operation is completed in one go, safe and smooth.

The two GENMA mobile harbor cranes (MHC) used in Akajutla Port were designed and built by Nantong Rainbow Heavy Machinery Co., Ltd. (abbreviation: Rainbow Heavy Machinery). The equipment is flexible and powerful, with a maximum working radius of 54 meters and a lifting capacity of 150 tons. It has a stable lifting capacity curve and can easily meet the trend of continuous large-scale development of marine ships.

On the premise of ensuring the safe and reliable operation of the boom, GENMA product designers have designed the equipment boom reasonably to give full play to the mechanical properties of the material and reduce the structural weight. The lightweight single-arm design and super high working speed help improve the efficiency of cargo loading and unloading. GENMA MHC can handle more than 30 containers per hour, which is not inferior to professional container handling equipment.

While committed to efficiency, GENMA also puts product safety first. In order to ensure the safety of production during container loading and unloading operations, GENMA product designers put the safety concept throughout the entire design process of MHC products.

Starting from the product structure, GENMA product designers cleverly designed the oil cylinder of the equipment that supports boom above the boom. Through scientific layout, the force of the cylinder is more reasonable, and at the same time, the collision of the goods with the cylinder during the lifting process is effectively avoided, eliminating the potential safety hazards.

GENMA MHC adopts the power distribution management system and the multi-axis drive hoisting system independently developed by GENMA in the core drive, which effectively improves the reliability of the equipment hoisting system.

In terms of intelligence, GENMA MHC is designed with an intelligent safety monitoring system, which can monitor the operation status of the equipment in real time, realize the functions of one-key leveling of the container, and anti-collision warning of the equipment, enhance the equipment support ability, and ensure the stable, efficient and safe operation. .

luipmention warning of the equipment, enhance the equipment support a

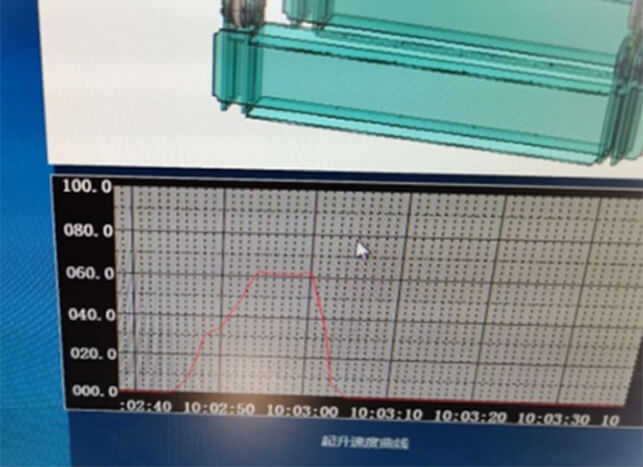

GENMA MHC has added hoisting/slewing speed waveforms to the user interface. Drivers can intuitively see the real-time speed, acceleration process and acceleration time of equipment lifting, providing accurate judgment for equipment lifting operations and improving equipment operating efficiency.

lhas added ho to offer one-key adjustment of goods to run smoothly

Due to the unstable center of gravity of cargo hoisting and other reasons, accidents such as container rollovers and slips occur from time to time. GENMA MHC can automatically monitor the status of the container through the horizontal sensor according to the position of the center of gravity of the container, realize one-key automatic leveling of heavy objects after the equipment is loaded, ensure the stability of the container lifting operation of the equipment, and improve the lifting efficiency of the equipment.

lunstable center of gravity of cargo hoisting and other reasons, ac

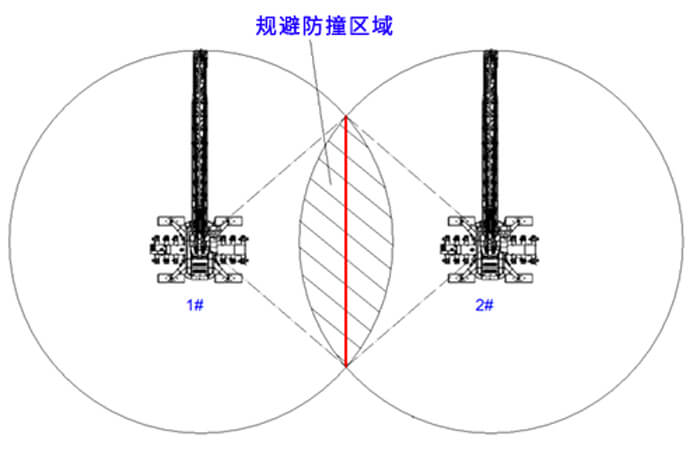

Given busy port operations, in order to meet the needs of the joint operation of the two MHC equipment and avoid the occurrence of collision accidents between the equipment, the GENMA product designers have made precise calculations to endow the GENMA MHC with the ability of multi-machine intelligent anti-collision warning.

Through calculation, the designers set the area range of the collision wall in advance. When the distance between the two MHC equipment is less than the danger radius, the front-end sensor of the boom will trigger its sound and light alarm device to enter the alarm state, in a bid to avoid the occurrence of collision accidents.

As a multi-functional "player", the advantages of GENMA MHC are far more than excellent stability, efficiency and safety. It also has super practicality. GENMA MHC can be equipped with various types of spreaders and grab buckets to meet the loading and unloading needs of various types of cargo such as containers, LNG tanks, general cargo and bulk materials, and various ship types. It is a comprehensive solution covering multiple scenarios and suitable for port transportation under various scenarios..

In addition to container handling, the two GENMA MHCs are also capable of handling bulk materials. Under the working condition of the grab bucket, the GENMA MHC grab bucket has an adaptive intelligent control function, which can automatically control the goods of different amplitudes and different densities, and make flexible choices to ensure the maximum grasping capacity. The grabbed goods will be loaded and unloaded according to the optimized path, which can effectively improve work efficiency and reduce the labor intensity of drivers.

It has been more than three years since the GENMA MHC was put into operation at the Port of Akajutla. For three years, GENMA MHC has impressed the customer team with its good product performance and comprehensiveness in handling materials, "GENMA's cranes are very good, easy to operate, and work great."

Use professional blueprints to deeply cultivate and benefit the industry. For more than ten years, Rainbow Heavy Machinery has been working intensively in the field of port machinery, and has provided mobile port cranes (MHC), bridge-type grab cranes, pneumatic grain ship unloaders, ship loaders and other various types of port machinery for many ports around the world. As a result, these products have won unanimous praise from customers in the industry for their high-quality products and services.

In the future, Rainbow Heavy Machinery will continue to improve the research and development capabilities and manufacturing capabilities of port equipment, devote itself to serving global port customers, and contribute to the construction of global smart ports with the power of Made in China.