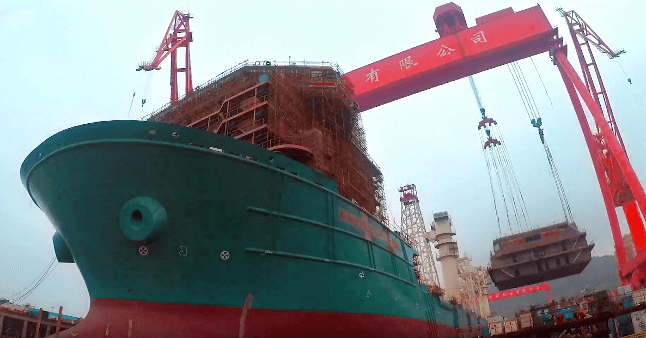

With the long blast of the whistle,the ships built by Fujian Mawei Shipbuilding Co., Ltd. (referred to as Mawei Shipbuilding) were successfully launched.After a hundred years, China's first modern shipyard has undergone several changes and development, continuing the Chinese dream of becoming a powerful maritime country.....

In 2015, Mawei Shipping purchased a 700-ton GENMA shipbuilding gantry crane (referred to as: shipbuilding gantry crane) from Nantong Rainbow Heavy Machinery Co., Ltd. (abbreviation: Rainbow Heavy Machinery), injecting new life into the shipbuilding business of the shipyard. energy of.

It has been more than 6 years since the equipment was delivered in 2015. It has participated in many major ships such as catamaran semi-submersible multi-purpose mobile platform, electric propulsion saturation diving support vessel, the world's first 227-meter deep-sea mining vessel, and seabed support and maintenance vessel. manufacturing items.

After the test of time and actual combat, Section Chief Chen, the head of Mawei Shipping Equipment, gave the following evaluation to the GENMA gantry crane: "The lifting capacity of the GENMA gantry crane and its use in the turning and closing operations of large hull sections are satisfactory. the performance of the whole machine is good, the positioning is accurate.”

- Intelligent frequency conversion control system makes the equipment run more reliably

In addition, the electric drive system adopts an independent motor drive device, which avoids the instability of the shared drive system and greatly improves the reliability and safety of equipment operation.

- Automatic positioning technology makes equipment operation more accurate

GENMA shipbuilding gantry adopts modern information technology, such as: automatic deviation correction, automatic positioning, lifting synchronization, electronic anti-sway, lifting anti-fall and information management technology, which further improves the automatic positioning level of equipment.

- Digital monitoring system makes personnel and equipment safer

GENMA shipbuilding gantry cranes have installed special shock-proof high-definition monitoring systems in several key parts, and comprehensively use microelectronics technology, information sensing technology and instant communication technology to monitor equipment operating data and operating behavior in real time, and monitor the equipment's possible abnormal conditions. , abnormal operation, etc. to give early warning, so that the safety of the equipment is in the "eyes".

Affected by marine environmental factors and working conditions, in addition to the precise and stable operation capability of the equipment itself, good environmental adaptability is also a necessary "professional quality" for a qualified shipbuilding gantry crane.

Windproof rail clamps, windproof cables, and wind speed and direction indicators are commonly used windproof devices in shipbuilding gantry cranes. However, due to the full consideration of safety, GENMA designers have also developed a set of safety protection system by themselves, which greatly improves the safety factor of the equipment through technical means such as deflection detection and deviation correction limit.

"For more than 6 years, the GENMA gantry crane has successfully withstood the test of many typhoon weather. In the typhoon season every year, the GENMA gantry crane is the last thing that worries us." Chief Chen recalled.

In addition, GENMA designers also comprehensively considered the environmental characteristics of the customer's site, such as high humidity and many salt spray components, and selected materials with good moisture-proof and corrosion-proof properties to improve product durability. After several years, the overall appearance of the device is still in good condition.

Whether the equipment is good or not will only be known after using it. After the actual use experience, the ship production staff and crane drivers of Mawei Shipping gave a thumbs up to the GENMA gantry crane

High-quality equipment is the best proof of brand strength. GENMA gantry crane has strong bearing capacity, large span and high lifting height, and has good lifting, positioning, and transportation functions. It can not only cover the manufacturing needs of current major ship types, but also withstand multiple tests of time, environment and actual combat!

Therefore, customers say that the good GENMA shipbuilding door machine is the right choice for you.