As we all know, shipping carries 90% of the total global trade in goods and occupies a very important position in the global trade in goods.

As a fast distribution center for cargo transportation, the normal operation of the port is inseparable from the auxiliary support of port machinery and equipment.

In order to meet the needs of port production and operation, Rainbow Heavy Machinery's own brand GENMA insists on independent innovation, research and development and lean manufacturing, continues to enrich its GENMA brand port equipment product line, and has successively launched catenary bucket ship unloaders, bridge-type grab ship unloaders, mobile port cranes, ship loaders, portal cranes and other port material handling equipment, providing professional solutions for port cargo loading, unloading and handling.

lsional-type grab ship unloader

GENMA bridge-type grab ship unloader adopts AC frequency conversion speed regulation control system, which is stable in operation, sensitive in response and easy to operate. With the advantages of excellent performance, safety and reliability, energy saving and environmental protection, GENMA bridge-type grab ship unloader is widely used in unloading operations of bulk cargo ships in various ports and terminals. In recent years, Rainbow Heavy Machinery has offered a number of bridge-type grab ship unloaders to a domestic iron and steel company and a papermaking company, and has garnered critical acclaim from clients for its outstanding product quality and service guarantee.

lbeen recognized and afunloader

Relying on the Pangkalan Susu wharf project in Indonesia, a set of catenary bucket ship unloader equipment designed and built by GENMA for the Indonesian National Power Company has been working stably for more than 1,000 days since delivery. Thanks to the advanced frequency conversion speed regulation control system adopted by GENMA catenary bucket ship unloader, the whole machine control system can adjust the ship moving speed in real time according to the actual ship unloading efficiency, and efficiently unload bulk materials such as coal, ore, sand and stone building materials.

lials such as coal, ore,

GENMA pneumatic ship unloader is a continuous unloading, fully enclosed conveying and innovative port machinery equipment independently developed by Rainbow Heavy Machinery according to the current market and environmental protection requirements. Based on the strategy of environmental protection and energy saving, the company has overcome a number of key technologies and developed two types of grain pneumatic ship unloader (referred to as: grain suction machine) and cement pneumatic ship unloader.

The GENMA pneumatic ship unloader innovatively adopts the multi-stage turbo blower technology with independent intellectual property rights and the brand-specific design of the dust collector and pleated filter bag, which can easily unload grains such as soybeans and corn, as well as various light materials such as cement and alumina. It is one of the preferred solutions for bulk material transportation in an environmental-friendly, highly efficient and high-quality manner.

lell GENMAial transportation in

瑞典Bruks Siwertell和润邦重机联合向国内市场推出的“润邦重机联合向国内市场推出的“a双品牌螺旋式卸船机设备采用了来自Siwertell 1972年发明的独特反向旋转喂料技术,卸料全程封闭,高效环保,清仓性高,尤其适用于煤炭、水泥和粮食的卸载,目前最高卸船效率可达3,000吨/小时。

The "Siwertell GENMA" dual-brand screw ship unloader equipment jointly launched by Sweden's Bruks Siwertell and Rainbow Heavy Machinery to the domestic market adopts the unique reverse-rotation feeding technology invented by Siwertell in 1972. The whole unloading process is closed, efficient and environmentally friendly. Owning to high clearance performance, it is especially suitable for coal, cement and grain unloading. Currently, the highest unloading efficiency can reach 3,000 tons/hour.

lMAhighest unloa

GENMA ship loader is one of the key equipment for bulk material loading operations, and is suitable for continuous ship loading operations of various bulk materials such as coal, ore, alumina, fertilizer, grain, etc. Relying on the features and advantages of high efficiency and environmental protection, GENMA ship loader is exported to domestic and overseas markets. At Balikpapan, the largest coal terminal in Indonesia, a 4,000-ton/hour GENMA ship loader is operating efficiently, sticking to the front line of ship loading operations.

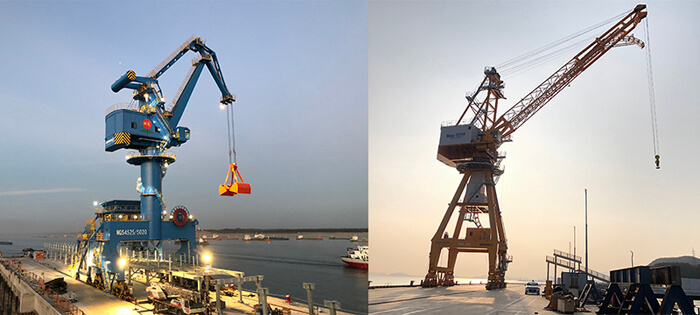

loportal crane

Portal crane is one of the featured products under the GENMA brand. According to the structure of the jib, it can be divided into two types: single jib and four-link. Compared with the general portal machine, the GENMA portal crane with finite element design is lighter in weight and more reasonable in force, and can run safely and smoothly in extreme weather. It has a wide range of applications, high operating efficiency, and stable machine operation, among others. In addition, this series of equipment can cope with various usage scenarios by matching different spreaders.

ltion, this series of eq

As the first mobile harbor crane (MHC) brand in Asia, GENMA has integrated intelligent path planning system, intelligent anti-sway system, intelligent energy storage management, and MHC multi-machine intelligence in GENMA's third-generation MHC after years of technical precipitation and iteration. Reliable anti-collision warning system and many other intelligent technologies have effectively improved the operation stability, environmental protection and safety of the equipment. GENMA MHC is capable of loading and unloading various cargoes such as containers, LNG tanks, general cargo and bulk materials, and is known as the "all-rounder" of the port.

lMAe first m

GENMA grabber is divided into two driving modes: diesel and electric. In terms of power, the GENMA full hydraulic grabber adopts advanced motor soft start, intelligent hydraulic control, intelligent power configuration optimization management and other technologies. The equipment has low energy consumption, high efficiency, strong stability, and high degree of automation. Various working devices such as shell grabs, plum flower grabs, log grabs, and electromagnetic suckers can be configured according to the diverse needs of customers, covering a wide range of material grabbing such as scrap steel, wood, sand, stone, coal, etc.

For more than a decade, under the "Belt and Road" Initiative, RHM has been deeply involved in the port machinery industry and actively explored the international market. Its GENMA brand has footprints in many major ports and terminals around the world. In the future, Rainbow Heavy Machinery will adhere to technological R&D and innovation, continuously promote product transformation and upgrading, and provide better and more professional solutions for material handling operations in ports and terminals.