Rainbow Cooperated with GustoMSC

21st Jul 2017, Shanghai

Keep An Eye on Trend, Keep on Moving

Throughout the company history, we can find out that Rainbow always keeps an eye on the industry trend and leading technology. Thus we have cooperated with many top brands till now. Such as Kalmar, Sandvik, FLSmidth, Rio Tinto and APM terminal, etc.

Further more, Rainbow cooperated with Cargotect to build strategical cooperation relation at 2012. Based on this tradition, Rainbow signed the strategic cooperation agreement with GustoMSC at 2015, who is the top player in the offshore wind area with high reputation and deep know-how. Rainbow and GustoMSC will work together to expand the market of 800-2000t leg encircling crane worldwide.

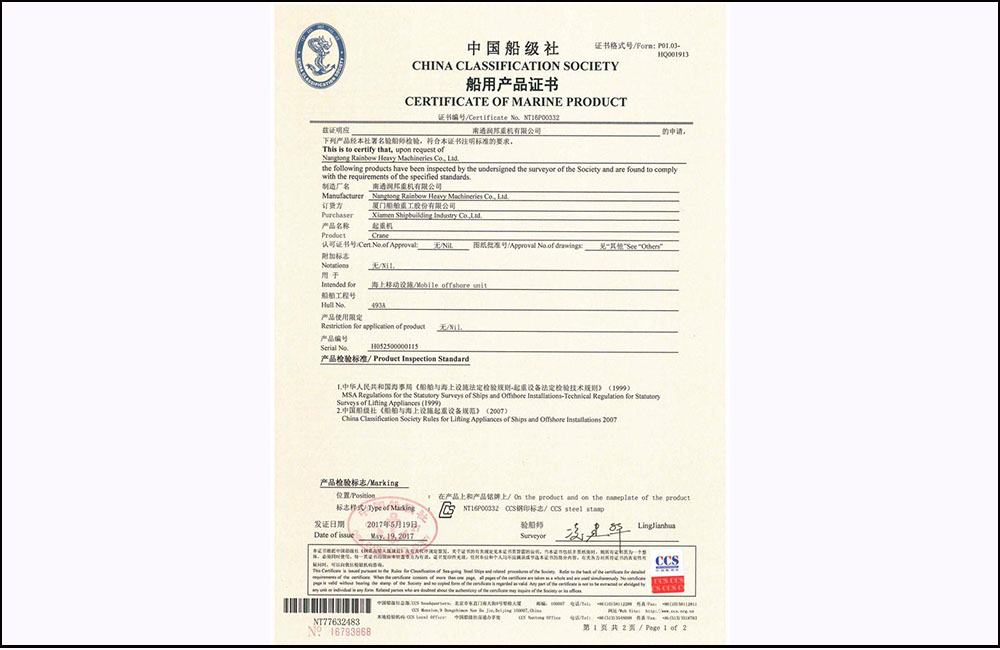

The 1st Delivered 1000t Marine Crane Received CCS Certificate

Recently, the first unit 1000t leg encircling crane, co-manufactured by Rainbow Heavy Machineries(RHM) and GustoMSC, received marine product certificate from China Classification Society (CCS) successfully.

Safe & Reliable Crane for Offshore Wind Installation

The 1st delivered crane with the maximum lifting capacity of 1000 tons, working radius ranging from 15.1 to 101 meters and maximum lifting height of 145 meters, is primarily used for offshore wind power installation and maintenance, can also be used for offshore heavy materials transport.

It offers a number of compelling advantages:

Weight Optimization

To reduce the weight, the crane is constructed out of high tensile steel where possible, which has a higher load bearing capacity and allows for a lighter construction.

Low Energy Consumption & High Efficiency

All movements of the crane are electrically driven by means of variable frequency drives. This system is more efficient and does not require power during standstill, thus uses less energy. The electric power supplies are transferred via a slip ring, which allows the crane to revolve limitlessly around its axis.

The crane has a small tail turning radius of 10 meters and the minimum working radius is 15.1 meters. The main hook can be split into two halves, in order to obtain a faster lifting speed and a more flexible operation. Meanwhile, the crane is equipped with 2 sets of constant tension systems, to ensure safety during operation.

Intelligence & Remote Control

The leg encircling crane uses a trolley slewing system. The slew bearing is advantageous over traditional slew mechanisms, which is easy to install, high stability and low maintenance cost. The real-time intelligent fault diagnostic system can quickly locate the malfunction. In addition, the crane can realize remote access to crane control system, to achieve remote service.

This certificated crane is the first crane ever since the cooperation between the two companies, which has been installed on the first offshore wind power platform in Fujian Province. The 2nd 1000t leg encircling crane is now in the erection stage, and is expected to move forward to commissioning procedure soon.

Keep An Eye on Trend, Keep on Moving

Throughout the company history, we can find out that Rainbow always keeps an eye on the industry trend and leading technology. Thus we have cooperated with many top brands till now. Such as Kalmar, Sandvik, FLSmidth, Rio Tinto and APM terminal, etc.

Further more, Rainbow cooperated with Cargotect to build strategical cooperation relation at 2012. Based on this tradition, Rainbow signed the strategic cooperation agreement with GustoMSC at 2015, who is the top player in the offshore wind area with high reputation and deep know-how. Rainbow and GustoMSC will work together to expand the market of 800-2000t leg encircling crane worldwide.

The 1st Delivered 1000t Marine Crane Received CCS Certificate

Recently, the first unit 1000t leg encircling crane, co-manufactured by Rainbow Heavy Machineries(RHM) and GustoMSC, received marine product certificate from China Classification Society (CCS) successfully.

Safe & Reliable Crane for Offshore Wind Installation

The 1st delivered crane with the maximum lifting capacity of 1000 tons, working radius ranging from 15.1 to 101 meters and maximum lifting height of 145 meters, is primarily used for offshore wind power installation and maintenance, can also be used for offshore heavy materials transport.

It offers a number of compelling advantages:

Weight Optimization

To reduce the weight, the crane is constructed out of high tensile steel where possible, which has a higher load bearing capacity and allows for a lighter construction.

Low Energy Consumption & High Efficiency

All movements of the crane are electrically driven by means of variable frequency drives. This system is more efficient and does not require power during standstill, thus uses less energy. The electric power supplies are transferred via a slip ring, which allows the crane to revolve limitlessly around its axis.

The crane has a small tail turning radius of 10 meters and the minimum working radius is 15.1 meters. The main hook can be split into two halves, in order to obtain a faster lifting speed and a more flexible operation. Meanwhile, the crane is equipped with 2 sets of constant tension systems, to ensure safety during operation.

Intelligence & Remote Control

The leg encircling crane uses a trolley slewing system. The slew bearing is advantageous over traditional slew mechanisms, which is easy to install, high stability and low maintenance cost. The real-time intelligent fault diagnostic system can quickly locate the malfunction. In addition, the crane can realize remote access to crane control system, to achieve remote service.

This certificated crane is the first crane ever since the cooperation between the two companies, which has been installed on the first offshore wind power platform in Fujian Province. The 2nd 1000t leg encircling crane is now in the erection stage, and is expected to move forward to commissioning procedure soon.