With the continuous acceleration of the global trade integration process, the bulk cargo throughput of major ports and terminals around the world continues to increase. Environmental pollution problems such as "loud noise" and "a lot of dust" generated in the traditional bulk cargo handling process have become increasingly prominent.

So, how to realize the transformation of bulk cargo handling from traditional to modern ways and then enable the construction of green ports? As a wholly-owned subsidiary of a state-controlled listed company with high-end equipment as one of its main businesses, Nantong Rainbow Heavy Machineries Co., Ltd. (abbreviation: RHM) offers the answer to the above question by adhering to the concept of green development and intelligent empowerment, and making constant technical innovation.

GENMA brand pneumatic ship unloader is a continuous unloading, fully enclosed conveying and innovative port machinery equipment independently developed by RHM in response to the current market and environmental protection requirements. It can easily unload grains such as soybeans and corn as well as light bulk materials like cement clinker. The maximum unloading capacity of the equipment is 600 tons/hour, which is suitable for ship types of 500-80,000 DWT. It can be designed as fixed type, rail type or tire type according to the actual situation of the terminal.

lAdvanced power technology to achieve energy saving and noise reduction

In terms of power, the GENMA pneumatic ship unloader innovatively adopts a multi-stage turbine fan with independent intellectual property rights to replace the traditional Roots blower, and is equipped with a variable frequency motor, which has high efficiency and low energy consumption. The self-adaptive wind pressure and air volume can effectively save the energy consumption of equipment operation. In addition, GENMA designers also took noise reduction measures for multiple noise sources of the equipment, which has well solved the problems of high energy consumption and loud noise of traditional pneumatic ship unloader.

In 2021, the GENMA grain pneumatic ship unloaders developed and customized by RHM for Guangxi Guigang Hailou Storage Service Co., Ltd. was successfully delivered. One year after the equipment was put into use, it has won high acclaim from customers for its performance advantages such as stable operation, low noise and obvious energy saving effect.

lMultiple dust removal technologies to suppress dust pollution

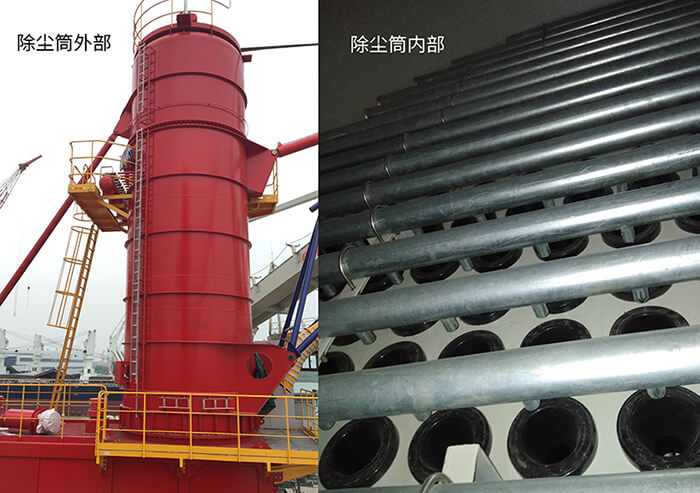

Aiming at the problem of dust pollution from bulk loading and unloading at dry bulk terminals, in addition to relying on sealed pipelines to eliminate dust pollution from bulk cargo unloading from the source, GENMA pneumatic ship unloaders combine gravity separation and filter bag separation technology. The unique design of dust removal cylinder and pleated filter bag is adopted, and the dust removal effect of the GENMA pneumatic ship unloader is doubled by increasing the filter area by more than 2 times.

On this basis, the GENMA (grain) pneumatic ship unloader also applies a new type of unpowered dust suppression technology with independent intellectual property rights at the exit of the unloading. Having adopted new dust suppression hopper, the equipment can adapt to the incoming material flow automatically during the operation, make the blanking more concentrated, and form a uniform dropping material column at the inner mouth of the hopper discharge port, so as to solve the problem of dust overflow during blanking and ensure on-site cleaning operations.

In addition to environmental protection, the design of the GENMA pneumatic ship unloader takes into account the conveying efficiency and quality of bulk materials.

Among them, in view of the material characteristics of cement that is easy to harden, the GENMA (cement) pneumatic ship unloader adopts a four-section hydraulic luffing boom design, and combines with a new type of rotating power suction nozzle, which can not only break up the accumulated materials, but also effectively absorb the dead corner residue cement in the cabin. As a result, the operation efficiency is improved while greatly lowering the clearance volume and reducing the operating cost of the terminal.

In order to ensure the integrity of grain transportation, the GENMA (grain) pneumatic ship unloader adopts the self-adaptive suction nozzle and detachable anti-wear elbow pipe independently developed by GENMA, which can make real-time detection and automatic adjustment of the suction nozzle depth inserted into the material. Using automation technology instead of the traditional manual control can improve the work efficiency, and reduce the probability of material crushing and improve the quality of grain transportation by forming a smooth anti-wear layer on the inner wall of the outer elbow pipe when the material passes through the elbow pipe.

GENMA pneumatic ship unloader has zero pollution, high efficiency, zero clearance, and stable operation. It is the preferred solution for environmental protection, high efficiency and high quality transportation of bulk materials. Today, GENMA pneumatic ship unloaders have been playing an active role in unloading bulk materials on the site of customers such as COFCO Jiujiang and Guangxi Guigang.

Under the international development trend of energy conservation and environmental protection, promoting the construction of green ports is the key to the sustainable strategic development of the port industry. It is believed that the environmentally friendly and efficient GENMA pneumatic ship unloader will definitely bring long-term comprehensive benefits to customers in the port industry.