Electricity is the power guarantee for economic and social development. Specifically, coal-fired power plays a dominant role in electricity supply in China because of its safety and reliability.

In order to improve the loading, unloading and transportation efficiency of thermal coal and ensure the needs of power plants in power generation, RHM has been committed to creating efficient and environmentally friendly coal loading, unloading and transportation solutions, and providing thermal power plants with various unloading services for ships to coal terminals, trains to coal storage yards, and so on.

Coal unloading (ship→ coal terminal)

GENMA Bridge-Type Grab Ship Unloader

GENMA bridge-type grab ship unloader is suitable for unloading coals of power plant at the dock. Possessing a simple working principle, it uses a mobile trolley to drive the grab bucket to grab the materials from the cabin, and then transport them to the rear yard through a hopper and a belt conveyor. However, what's not simple is that the GENMA bridge-type grab ship unloader control system can automatically plan the optimal operating trajectory of the grab bucket according to the boundary conditions set by the driver, automatically complete the hopper grabbing operation in a safe and efficient manner, and greatly reduce the driver's labor strength at the same time.

Features:

The main mechanism adopts the AC frequency conversion speed regulation control system based on vector control; each mechanism is provided with stepless speed regulation, stable starting and braking functions, and quick response;

The whole machine is featured with high productivity, wide application range, mature technology, stable work and convenient maintenance.

Efficiency: ★★★★☆

Environmental protection: ★★★☆☆

Economy: ★★★★★

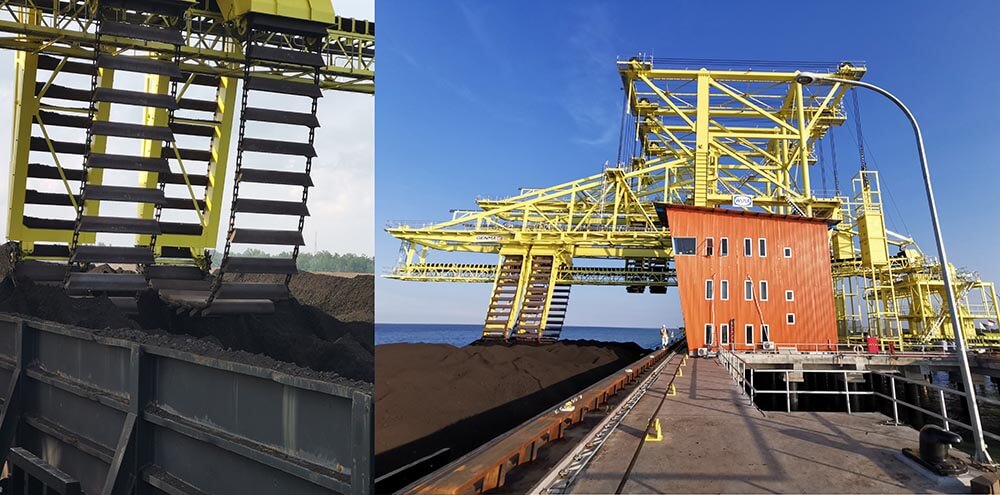

GENMA Catenary Chain Bucket Ship Unloader

GENMA catenary chain bucket ship unloader is a continuous bulk material conveying equipment, which is professionally used in continuous coal unloading operations. The GENMA catenary chain bucket ship unloader adopts an advanced frequency conversion speed regulation control system. The whole machine control system can make a real-time adjustment of the ship-moving speed according to the actual ship unloading efficiency, so as to ensure the efficiency of the ship unloader in a stable state.

Features:

The equipment adopts multi-row chain control, which has the characteristics of flexibility, high efficiency and stable unloading;

The semi-closed material unloading structure can reduce the leakage and dust of the material, and all the material transfer points are equipped with dust removal devices for dust suppression to meet the needs of green coal transportation;

It has low sensitivity to wind and waves on the water surface. When the barge bumps up and down due to wind and waves, the reclaiming part of the ship unloader will not be damaged after experiencing collision with the cabin. Therefore, it has good environmental adaptability.

Efficiency: ★★★★★

Environmental protection: ★★★★☆

Economy: ★★★★☆

GENMA Mobile Harbor Crane (MHC)

Mobile Harbor Crane (MHC), a characteristic product under GENMA, is flexible and maneuverable. GENMA MHC is capable of loading and unloading multiple types of cargo such as containers, LNG tanks, general cargo and buck materials. Known as a generalist of port, it is applicable to various types of ship from barges to over-Panamax.

Features:

Easy operation, driver room operation and remote operation are both available;

The rotary function facilitates automatic centering under the condition of nearly 0° and 180°, smart control and easy operation;

MHC energy distribution management technology and adaptive intelligent control can be customized according to user needs, in order to save energy, reduce consumption and improve work efficiency.

Efficiency: ★★★★☆

Environmental protection: ★★★☆☆

Economy: ★★★☆☆

Usage: ★★★★★

Siwertell GENMA Screw Ship Unloader

Siwertell GENMA screw ship unloader is a kind of buck cargo unloading equipment with screw conveyor and special reclaiming device as the main working mechanism, and works in a high efficient and continuous manner. At present, it is capable of unloading a maximum of 3,000 tons per hour, almost one ton of coal per second, and is especially suitable for unloading coal, cement and grain.

Features:

The closed structure design can ensure that the goods are transported without leakage during the whole process, and effectively ensure the cleanliness of the job site environment.

Unique counter-rotating inlet feeder invented by Siwertell in 1972 is adopted. This technology, featured with strong maneuverability and high clearance, can effectively penetrate into the surface of bulk materials, and unload materials layer by layer continuously.

Efficiency: ★★★★★

Environmental protection: ★★★★★

Economy: ★★★☆☆

Coal unloading (train→coal yard)

GENMA Grabber

The GENMA hydraulic grabber can grab coal from the train cargo box and transport it to the coal yard of the power plant. The equipment is divided into two driving modes: diesel and electric, and the slewing platform can rotate 360hydraulic grabber can grab coal from the train cargo box and transport it to the coagrab buckets, shell grab buckets, electromagnetic suction cups, log grab buckets, among others can also be attached to adapt to various operational needs. Meanwhile, it is applicable to scrap steel, ore, mineral powder, coal, sand, wood and other bulk materials.

Features:

Provided with the intelligent hydraulic control system, the equipment can automatically adjust the output power, so that the prime mover can work stably and reliably under the best working conditions;

Using advanced motor soft start and intelligent power configuration optimization management technology, the equipment has low energy consumption, high efficiency, strong stability and high degree of automation.

Efficiency: ★★★★☆

Environmental protection: ★★★☆☆

Economy: ★★★★★

Usage: ★★★★☆

Coal transfer (coal terminal→ coal yard→workshop)

KOCH stacker, reclaimer, stacker-reclaimer