Under the guidance of the strategic goal of "carbon peaking and carbon neutrality", the global trend of building smart green ports is on the rise.

Port machinery equipment is an indispensable and important component in the production and operation of modern port projects. In the context of the increasingly urgent demand for energy conservation and environmental protection, the experimental research on energy-saving methods for hoisting equipment has received extensive attention.

Lifting and lowering are the most frequent mechanical actions of lifting equipment. In the process of unloading the equipment load, huge mechanical energy is often converted into heat energy and wasted in vain. A set of GENMA crane hydraulic energy feedback system has been successfully developed.

It has been verified by tests that the GENMA crane hydraulic energy feedback system can effectively reduce the power consumption of the engine, save 25%-30% of energy for the whole machine, and at the same time prolong the life cycle of the equipment and reduce the cost of equipment use.

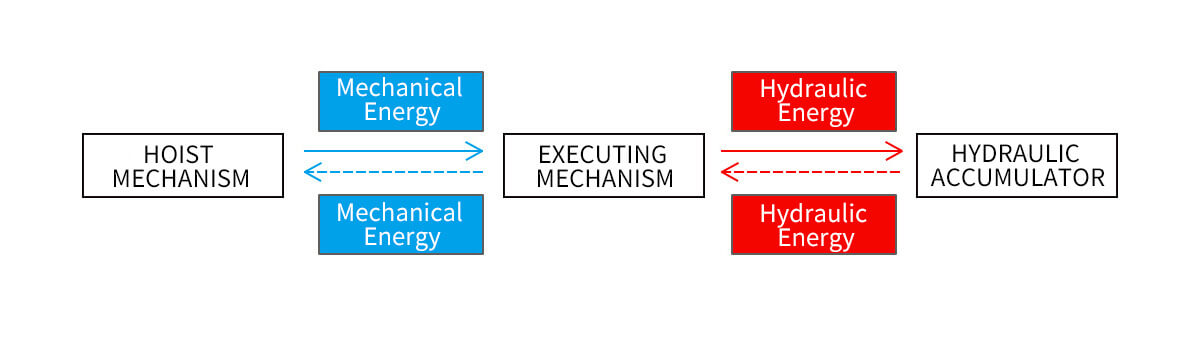

GENMA crane hydraulic energy feedback system can also be called GENMA energy feedback technology. It refers to an energy self-circulation system that can convert the mechanical potential energy generated when the crane load is lowered into hydraulic energy and store it for crane lifting operations.

hoisting mechanism /Mechanical energy/conversion device/hydraulic energy/energy storage device

Although the principle of GENMA energy feedback technology does not sound complicated, it is not easy to do this "simple" thing well.

Due to the matching switching between the GENMA crane hydraulic energy feedback system, the main system and the anti-drag braking system, the stability of the equipment and safe operation are directly related. How to control the energy transmission between the systems and match the intervention timing of different systems has become the The key points and difficulties of system technology research and development.

"We have adopted the electro-hydraulic proportional and constant torque control technology in the hydraulic energy feedback system of GENMA crane, which can precisely control the energy transmission ratio of the equipment under various working conditions, and complete the energy exchange within the equipment. In order to achieve the purpose of energy saving and consumption reduction." GENMA technical research and development personnel introduced.

"In addition, for the difficult problem of precise control of system intervention nodes, we repeatedly tested and verified the control time parameters of key components such as hydraulic pumps and hydraulic motors, and finally successfully maintained the energy recovery intensity within a delicate balance range , to ensure the smooth operation of the equipment during the system switching process.Or to put it more intuitively, if the energy transmission data is not carefully observed, it is difficult for the driver to even detect when the energy recovery system intervenes, and the safety and reliability of the equipment operation can be fully guaranteed. "

Excellent

In addition to all-round consideration of system functions and practical use, GENMA technical R&D personnel have also kept pace with the times in the design of the system client, bringing intelligence and humanization to the extreme.

In order to facilitate the driver to intuitively understand the energy transmission status of the equipment, GENMA technical developers have designed an independent control page for the system. Through the LCD screen, the driver can not only view various data of the system operation in real time, but also activate the energy feedback system with one key in the interactive design of the touch screen, and turn on the energy-saving mode of the equipment with one key.

GENMA crane hydraulic energy feedback system has practical functions such as energy saving, environmental protection, stability and reliability, convenient operation, and easy management. It can be widely used in mobile port crane (MHC) equipment and crane products using electro-hydraulic proportional control system. Effectively reduce equipment power and play a positive role in energy saving and consumption reduction of port machinery equipment.

The successful breakthrough of GENMA energy feedback technology is not only another new achievement of Rainbow Heavy Machinery's technological innovation, but also a new footnote for the company to actively practice the concept of green development and lead the industry's green upgrade.

In the future,RHM will continue to devote itself to the research and development and innovation of new technologies and new products, adding new impetus to accelerate the construction of green ports.