With the rapid development of the economy, the demand for grain transportation has grown significantly, and waterway transportation has become the main mode of transportation for bulk materials such as grain due to its large loading capacity and low cost.

However, the large amount of dust generated during the loading and unloading of bulk cargoes not only pollutes the environment of the terminal, but also affects the occupational health of the workers on site, and due to the flammable and explosive nature of the dust, there are also huge safety hazards at the loading and unloading operation site.

How to control dust pollution and build a greener bulk cargo terminal has become a pressing problem for enterprises in the industry to solve.

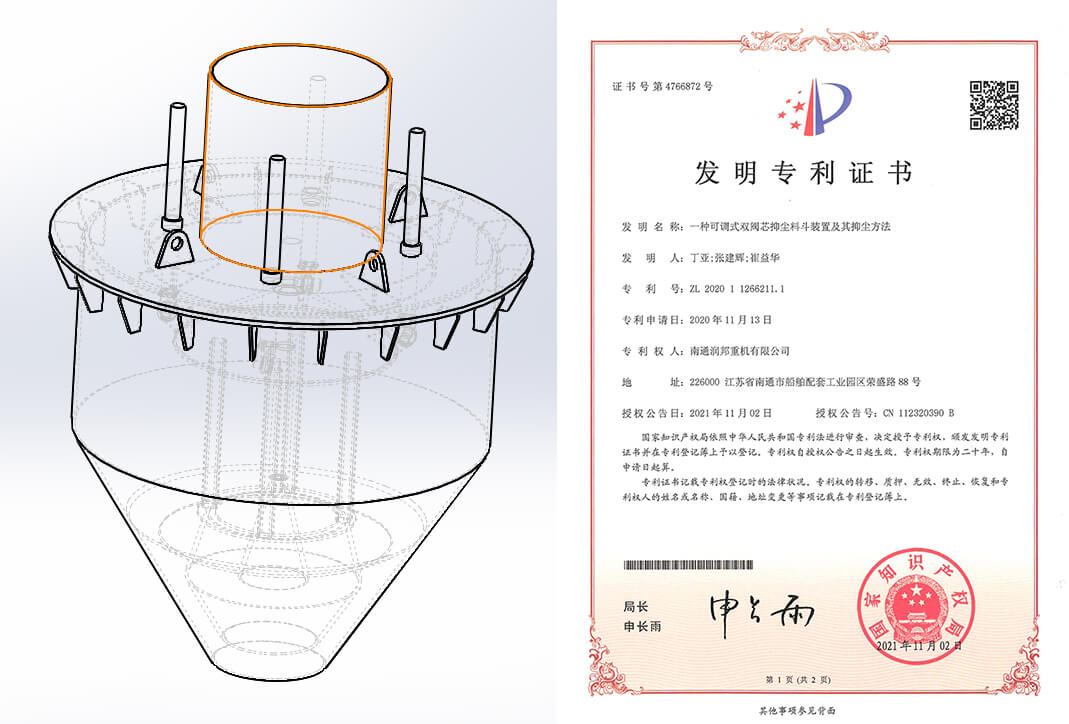

Nantong Rainbow Heavy Machinery Co., Ltd (hereinafter referred to as: RHM) actively advocates and practices the concept of green and sustainable development in China, and its GENMA material handling equipment brand has successfully developed an adjustable non-powered dust suppression hopper (also known as: non-powered dust suppression technology), and obtained a national invention patent by virtue of its innovative R&D design and leading edge in application technology.

- The principle is simple, no additional power is required

Different from the traditional dust suppression method, this technology does not need external driving forces such as electric power system and human intervention, but only needs to use the airflow inside the hopper to effectively solve the problem of dust pollution in the process of bulk material loading and unloading. It has truly achieved the "no power" dust suppression in the true sense.

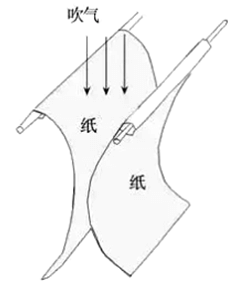

The working principle is like taking two sheets of paper and blowing into the middle of them, you will find that instead of floating outwards, the paper will be squeezed together by a force. In the same way, loose material falls through the hopper at high speed to form a column, carrying dust that is squeezed inwards by the airflow.

GENMA's powerless dust suppression technology makes clever use of aerodynamic principles to wrap fine dust in the centre of the column, thus achieving dust suppression and also avoiding explosive accidents caused by high dust concentrations.

- "Intelligent" dust suppression without blocking or spreading

GENMA's powerless dust suppression technology is not only effective and environmentally friendly, but also energy and noise free as it does not require the use of electrical energy and electrical equipment, this technology also has the advantages of energy saving and cost reduction, which can be said to be very "independent" and "excellent". "What's even better about this technology is that it can also adapt well to different loading and unloading flows, "intelligently" suppressing dust and solving the disadvantages of traditional hoppers such as easy blocking and spreading of material, significantly improving the efficiency and quality of bulk material loading and unloading.

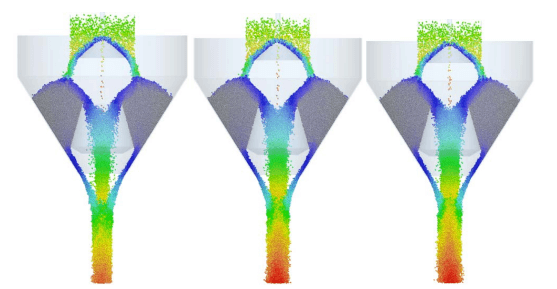

"When the incoming flow is less than the maximum outgoing flow, the bulk material in the hopper cannot form an accumulation, and the bulk material falls fast and loosely, resulting in serious dust pollution; when the incoming flow is greater than the maximum outgoing flow, the excess bulk material will keep accumulating in the hopper, which will easily lead to the overflow of bulk material and cause waste of bulk material. " GENMA's technical development staff described.

"In response, we have designed an adaptive adjustable device in the GENMA dust suppression hopper, which, together with the dividing device, allows precise control of the hopper infeed and outfeed flow ratios to suit different bulk material handling efficiencies and maintain good dust suppression. At the same time, the accumulation and spreading of material is effectively eliminated, greatly reducing the loss of bulk material."

In response to the above solution, the technical developers fully considered the various possibilities in the hopper discharging process and conducted several simulation tests on the hopper discharging effect using professional software to ensure that the new hopper can form a stable accumulation of material within a certain inlet flow range through its self-adjustment function, ensuring the smoothness of the hopper discharging operation.

The perfect combination of the powerless and adjustable features of the GENMA dust suppression hopper not only achieves the goal of energy saving and environmental protection, but also reduces the labour intensity of the site operator and ensures a safe and healthy working environment.

GENMA non-powered dust suppression hopper dust removal concept is novel, fully functional, does not consume power, dust suppression efficiency is high, is a true environmentally friendly dust removal device, suitable for grain and other bulk material conveying system transfer station (loading, packing) scene of dust management. Nowadays, this hopper has been successfully applied on grain pneumatic ship unloader projects in Guangxi Guigang, Jiujiang COFCO and Nantong Tonghaitang, which have been positively evaluated by customers.

Under the new situation of energy crisis and environmental protection, building a green port is the only way for the development of ports and the key to solving various problems encountered by ports in their development process. R&B Heavy Machinery will continue to give full play to its technological advantages, strengthen the application of technological innovation in port scenarios, and continuously promote the construction of green ports with high-tech empowerment.