Do You Really Know about the Quality of Made-in-China?

24th Oct. Shanghai

When talking about made-in-china, what comes to your mind? Mostly mentioned word is cheap and low-quality is the second high-frequency vocabulary. Is this the complete truth? The follow case maybe will change your mind.

Recently, Rainbow Heavy Machineries(RHM) delivered one unit 6000TPH stacker-reclaimer to Port of Hay Point, Australia.

Stacker-reclaimer is a kind of high-tech and large equipment used in mining industry, which requires superior design and manufacture process. Apart from excellent design, manufacture and quality control is very important for a successful project. Only with this, the fine design could be turned into reality, and customer demand could be fully satisfied.

Following info reveal RHM’s pursuit for excellent quality and strict quality control about this project.

Material ID Implements Traceability

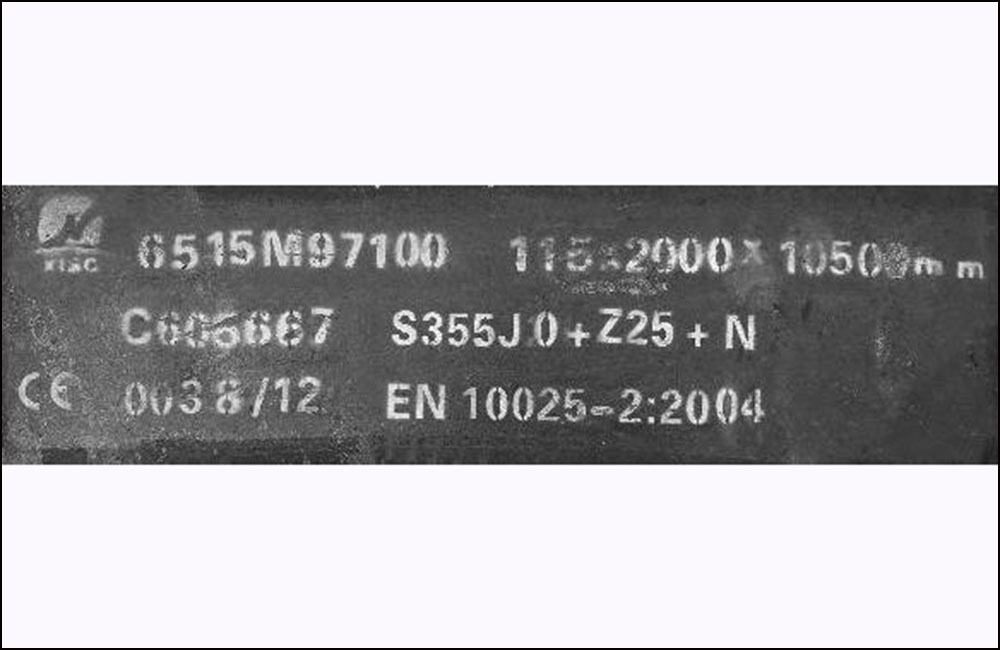

This product uses EN10025-2 S355J0 steel plate. Apart from EN standard, it also has special requirements in grain size, boron, yield strength and tensile strength, through-thickness tensile, UT detection, etc.

Each piece and each part owns a specific ID, recording in detail of material and drawing sources, thus make it available for quality traceability afterwards.

Strictly Monitor the Welding Procedure

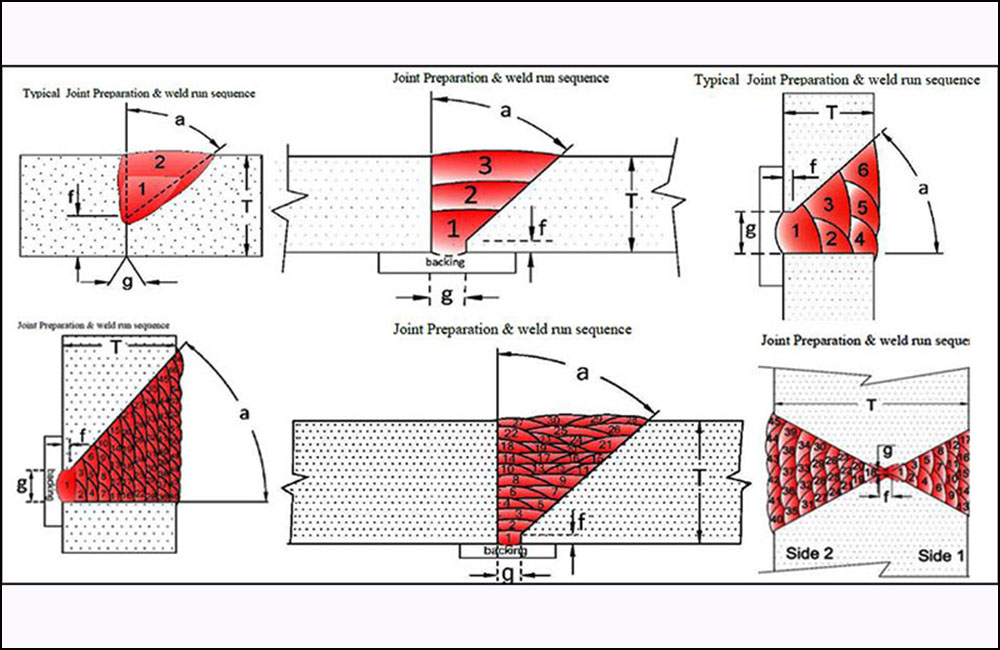

Because of large-scale and irregular characteristics of the machine parts, great skill is required in welding process. As showed in Figure 3, welding technicians are conducting strict symmetric welding to ensure welds quality and avoid the deformation from welding stress. While at the same time quality control technicians are monitoring and recording throughout the whole process.

Each product, each part and each weld uses different welding procedure accordingly. Reliability of the welding parts can be guaranteed by the strict implementation of the technology regulation and standard.

Welding Qualification Rate Up to 99.99%

Each weld shall undergo 4 strict inspection procedures, respectively from welding supervisor, quality control engineer, customer inspector and the client representatives. The key weld length totals up to 23,799 meters, among which only 80.1 meters are unqualified, the welding qualification rate reaches as high as 99.99%.

18 Painting Procedures Guarantee 10 Years Anti-corrosion

The machine goes through 18 painting procedures. Abrasive blasting quality reaches ISO8501-1 Sa2.5 degree, fully cleans the rusts, oxide skins and other impurities on the surface of steel structure, to strengthen cohesive force of the primer and finish paint, safely protect the machine from corrosion. Benefit from this, 10 years anti-corrosion guarantee could be provided.

Meticulously in Details

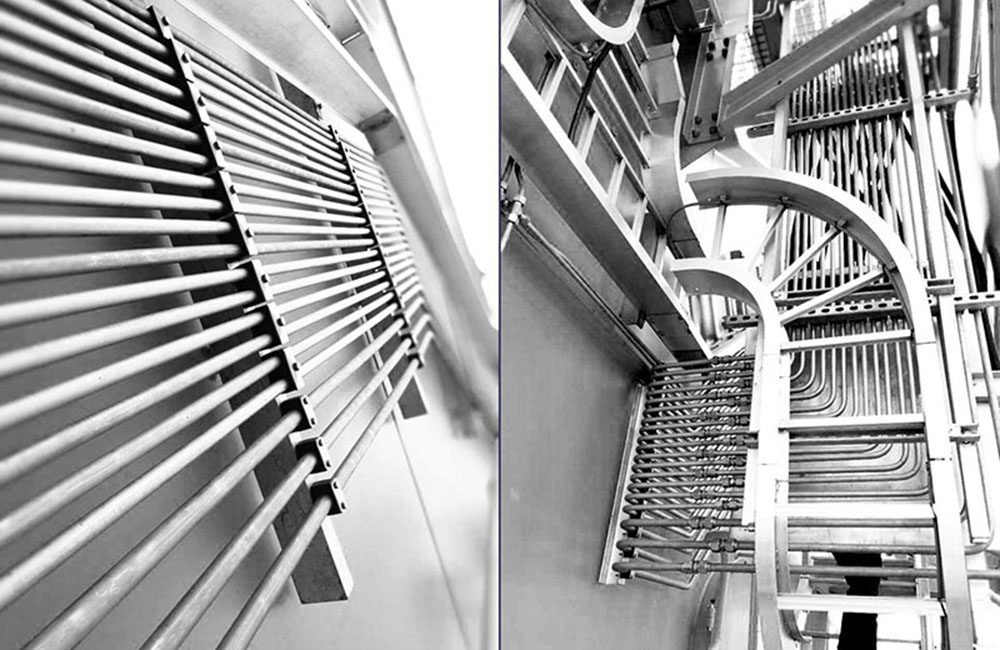

Mechanical and electrical installation is also an important detail revealing quality. The pipelines and cable ladders are tidy and well-organized inside the stacker-reclaimer.

When talking about made-in-china, what comes to your mind? Mostly mentioned word is cheap and low-quality is the second high-frequency vocabulary. Is this the complete truth? The follow case maybe will change your mind.

Recently, Rainbow Heavy Machineries(RHM) delivered one unit 6000TPH stacker-reclaimer to Port of Hay Point, Australia.

Stacker-reclaimer is a kind of high-tech and large equipment used in mining industry, which requires superior design and manufacture process. Apart from excellent design, manufacture and quality control is very important for a successful project. Only with this, the fine design could be turned into reality, and customer demand could be fully satisfied.

Following info reveal RHM’s pursuit for excellent quality and strict quality control about this project.

Material ID Implements Traceability

This product uses EN10025-2 S355J0 steel plate. Apart from EN standard, it also has special requirements in grain size, boron, yield strength and tensile strength, through-thickness tensile, UT detection, etc.

Each piece and each part owns a specific ID, recording in detail of material and drawing sources, thus make it available for quality traceability afterwards.

Strictly Monitor the Welding Procedure

Because of large-scale and irregular characteristics of the machine parts, great skill is required in welding process. As showed in Figure 3, welding technicians are conducting strict symmetric welding to ensure welds quality and avoid the deformation from welding stress. While at the same time quality control technicians are monitoring and recording throughout the whole process.

Each product, each part and each weld uses different welding procedure accordingly. Reliability of the welding parts can be guaranteed by the strict implementation of the technology regulation and standard.

Welding Qualification Rate Up to 99.99%

Each weld shall undergo 4 strict inspection procedures, respectively from welding supervisor, quality control engineer, customer inspector and the client representatives. The key weld length totals up to 23,799 meters, among which only 80.1 meters are unqualified, the welding qualification rate reaches as high as 99.99%.

18 Painting Procedures Guarantee 10 Years Anti-corrosion

The machine goes through 18 painting procedures. Abrasive blasting quality reaches ISO8501-1 Sa2.5 degree, fully cleans the rusts, oxide skins and other impurities on the surface of steel structure, to strengthen cohesive force of the primer and finish paint, safely protect the machine from corrosion. Benefit from this, 10 years anti-corrosion guarantee could be provided.

Meticulously in Details

Mechanical and electrical installation is also an important detail revealing quality. The pipelines and cable ladders are tidy and well-organized inside the stacker-reclaimer.

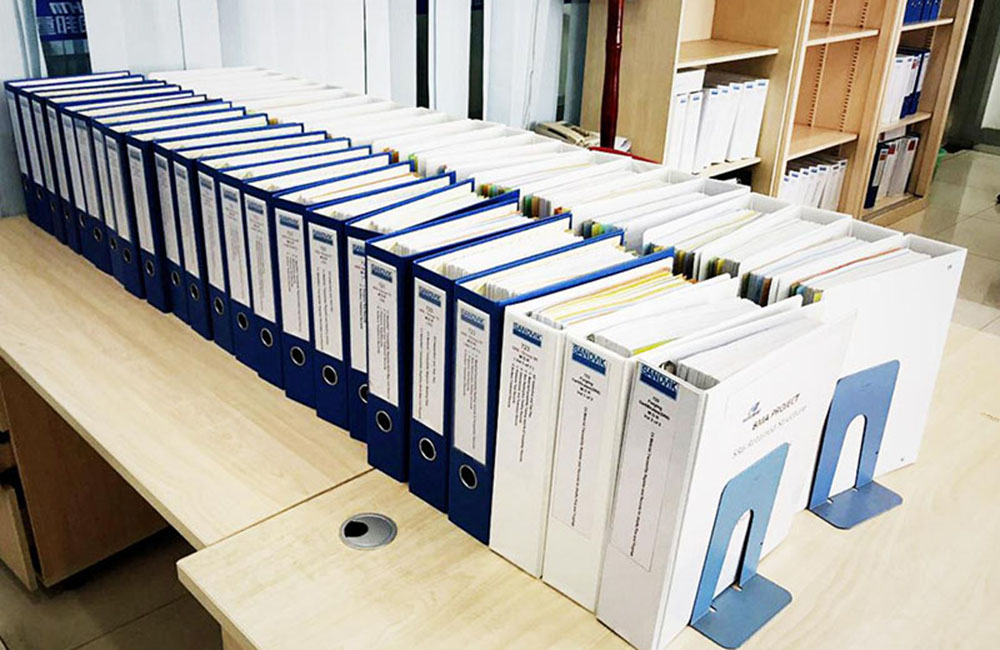

Advanced PM and QM

More than 20,000 pages of project related MDR are archived. With nearly 20 years experience and deep know-how in port and other industries, RHM has delivered more than 4000 equipments to 20 countries. Based on this, Rainbow has developed the project and quality management to a maturity level. From the glance of the video of customer testimony, you can get the proof. (get more info. from the customer testimony video)