- +86 0513-80108718

- GENMA@RAINBOWCO.COM.CN

- 8613584712931

Gemma GGU bridge grab ship unloader is mainly used for bulk material unloading. Use the steel wire rope to control the grab to grab the material and unload it to the belt conveyor or truck.

Wire rope traction type: The opening and closing, lifting and running of the grab are driven by the machine room. The trolley is hauled by a steel wire rope, and the trolley has the advantages of light weight and fast speed.

Trolley type: The opening and closing, lifting and running of the grab are driven by a trolley. The optimized cockpit design features a wide field of view and easy control. The shorter the wire rope, the less wear.

-

-

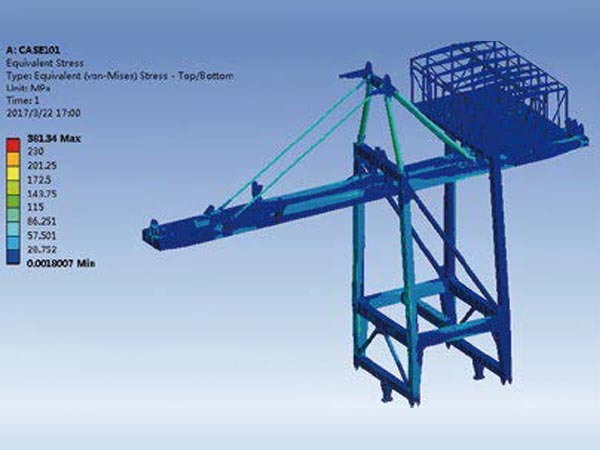

ANSYS计Calculate 3D model design

ANSYS计Calculate 3D model design

All structures of Gemma grab ship unloader, after

ANSYS calculation to ensure strength, rigidity,

stability. All parts pass the 3D simulation group

Installed, after repeated inspections and performance confirmation before manufacturing.

-

-

-

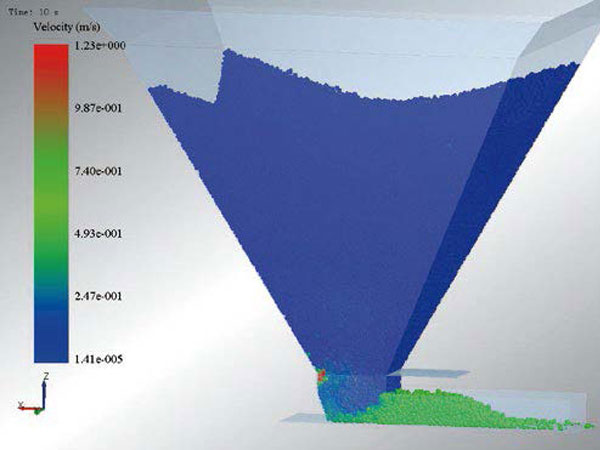

EDEM: Bulk material operation simulation

EDEM: Bulk material operation simulation

-

-

-

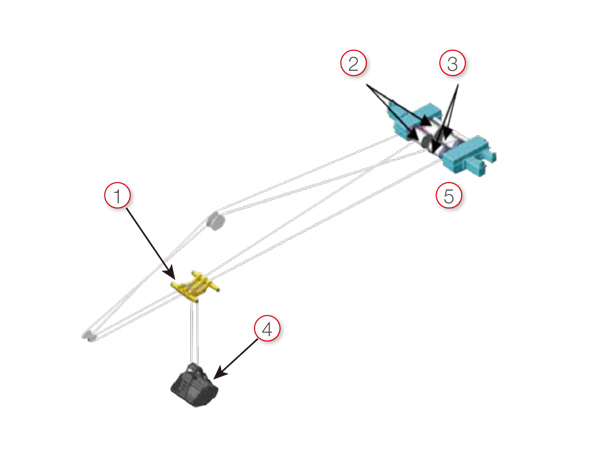

Four-drum mechanical differential lifting/opening and closing mechanism and traction trolley

Four-drum mechanical differential lifting/opening and closing mechanism and traction trolley

1—Grab trolley

2—Lifting reel

3—Close the reel

4—Grab

5—Differential reducer

-

-

-

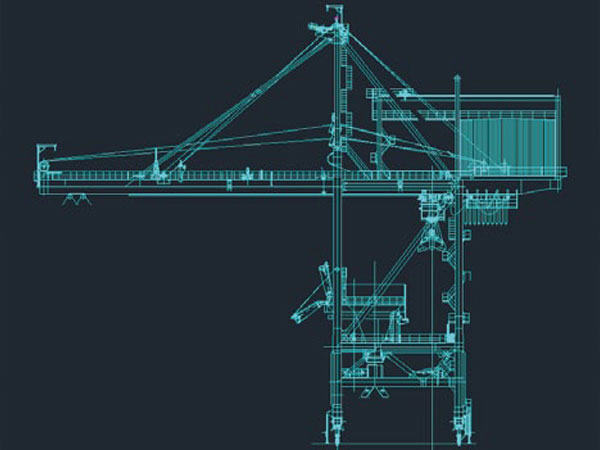

Lightweight body

Lightweight body

The original independent promotion, opening and closing The mechanism and the traction of the trolley are combined into a simple Single structure, wear-resistant and compact structure The steel wire winding system reduces the wire rope The amount in turn reduces the total weight of the machine.

-

-

-

New environmental protection

New environmental protection

Increase the electrical energy feedback function interface to convert the potential gravitational energy into Electric energy, effectively reducing energy consumption; in addition, we also consider optimization Speed of each organization and optimize its performance.

-

-

-

Structural optimization

Structural optimization

The crane design has been optimized from two aspects:

1. The height of the center of gravity of the crane and the height of the windward surface.

2. Through the speed optimization and electrical control of each mechanism, the crane Run smoothly and efficiently.

-

-

-

Perfect combination, stable performance

Perfect combination, stable performance

If the crane is regarded as a human being, the steel structure is the skeleton, the program is the core of wisdom, and the components should be the organs. These three elements are indispensable. In our design, mechanical and electrical The sub and component parts are perfectly combined.

-

-

-

Intelligent, digital

Intelligent, digital

Remote monitoring system Fault diagnosis system Energy feedback system...

-

■Efficiency range: 400-3000TPH

■Provide personalized customized solutions

Typical model table

| Rated parameters | 400Tons/hour | 1750Tons/hour | 3000Tons/hour |

|---|---|---|---|

|

Maximum liftspeed |

65 M/min | 130 M/min | 190 M/min |

|

MaximumOpening and closingspeed |

130 M/min | 180 M/min | 190 M/min |

|

TotalLift height |

20 meter | 34.5 meter | 42.6 meter |

|

RailUpper lifting height |

13 meter | 22 meter | 21.3 meter |

|

RailLower lifting height |

7 meter | 12.5 meter | 21.3 meter |

|

Trolley running speed |

80 M/min | 220 M/min | 240 M/min |

|

Reach |

19 meter | 33 meter | 40 meter |

|

Back reach |

7.5 meter | 14 meter | 44 meter |

|

Cart runningspeed |

0~20 M/min | 0~20 M/min | 0~25 M/min |

|

gauge |

10 meter | 20 meter | 20 meter |

|

Grab |

4-rope grab | 4-rope grab | 4-rope grab |

-

-

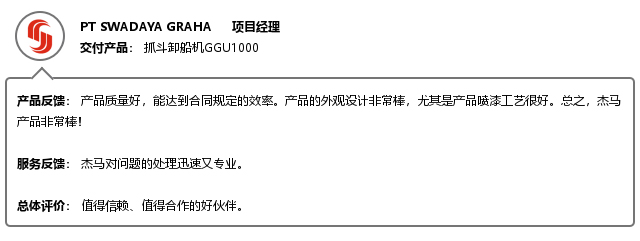

model:GGU1000

model:GGU1000

customer:Cigading Port, Indonesia(Cigading port)

efficient:1000Tons/hour

Quantity: 1

Lifting capacity:25t

Total lifting height:34m

More details

-

-

-

•Compact, low-maintenance structure: lifting, opening and closing, and the rope trolley are integrated. The whole structure is more compact, less abraded and lighter.

• Low maintenance: Excellent lubrication system reduces maintenance.

•High efficiency and low noise: parallel movement straight up and down, reducing the rotation function, high productivity and stable performance.

•Select well-known brands for electronic components: electronic components can choose well-known brands based on user needs and preferences